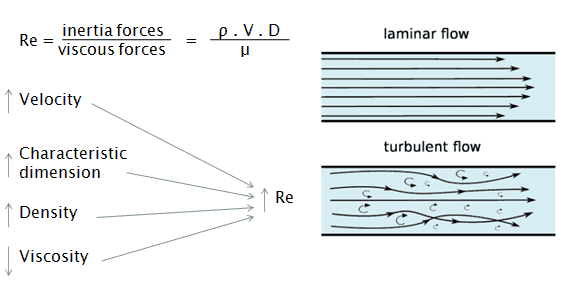

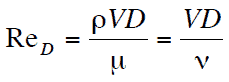

Reynolds Number Formula

The Reynolds number is the ratio of inertial forces to viscous forces and is a convenient parameter for predicting if a flow condition will be laminar or turbulent. It can be interpreted that when the viscous forces are dominant (slow flow, low Re) they are sufficient enough to keep all the fluid particles in line, then the flow is laminar. Even very low Re indicates viscous creeping motion, where inertia effects are negligible. When the inertial forces dominate over the viscous forces (when the fluid is flowing faster and Re is larger) then the flow is turbulent.

It is a dimensionless number comprised of the physical characteristics of the flow. An increasing Reynolds number indicates an increasing turbulence of flow.

The Reynolds number formula is:

where:

V is the flow velocity,

D is a characteristic linear dimension, (travelled length of the fluid; hydraulic diameter etc.)

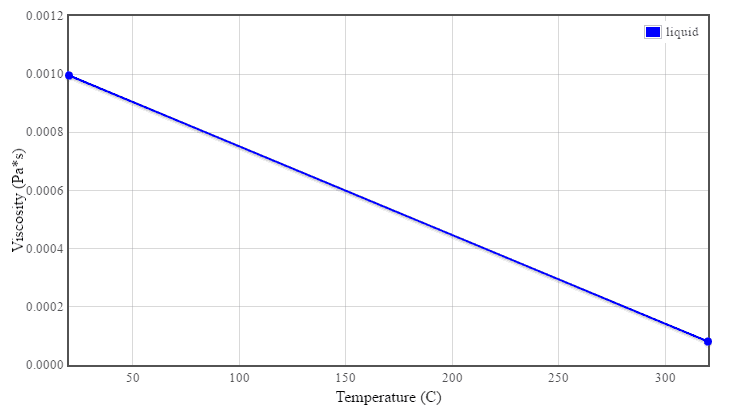

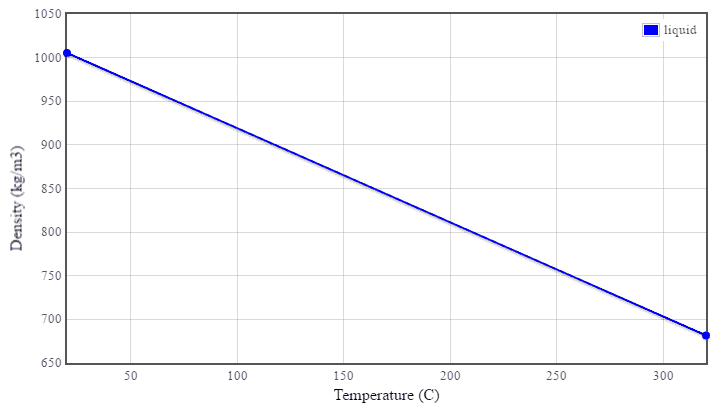

ρ fluid density (kg/m3),

μ dynamic viscosity (Pa.s),

ν kinematic viscosity (m2/s); ν = μ / ρ.

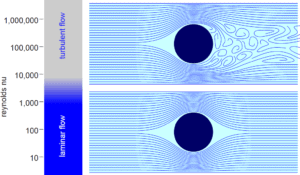

Laminar vs. Turbulent Flow

Laminar flow:

- Re < 2000

- ‘low’ velocity

- Fluid particles move in straight lines

- Layers of water flow over one another at different speeds with virtually no mixing between layers.

- The flow velocity profile for laminar flow in circular pipes is parabolic in shape, with a maximum flow in the center of the pipe and a minimum flow at the pipe walls.

- The average flow velocity is approximately one half of the maximum velocity.

- Simple mathematical analysis is possible.

- Rare in practice in water systems.

Turbulent Flow:

- Re > 4000

- ‘high’ velocity

- The flow is characterized by the irregular movement of particles of the fluid.

- Average motion is in the direction of the flow

- The flow velocity profile for turbulent flow is fairly flat across the center section of a pipe and drops rapidly extremely close to the walls.

- The average flow velocity is approximately equal to the velocity at the center of the pipe.

- Mathematical analysis is very difficult.

- Most common type of flow.

We hope, this article, Reynolds Number Formula, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.