Learn about Phase Change Materials (PCMs), substances crucial for energy storage and regulation by leveraging latent heat during state transitions.

Understanding Phase Change Materials

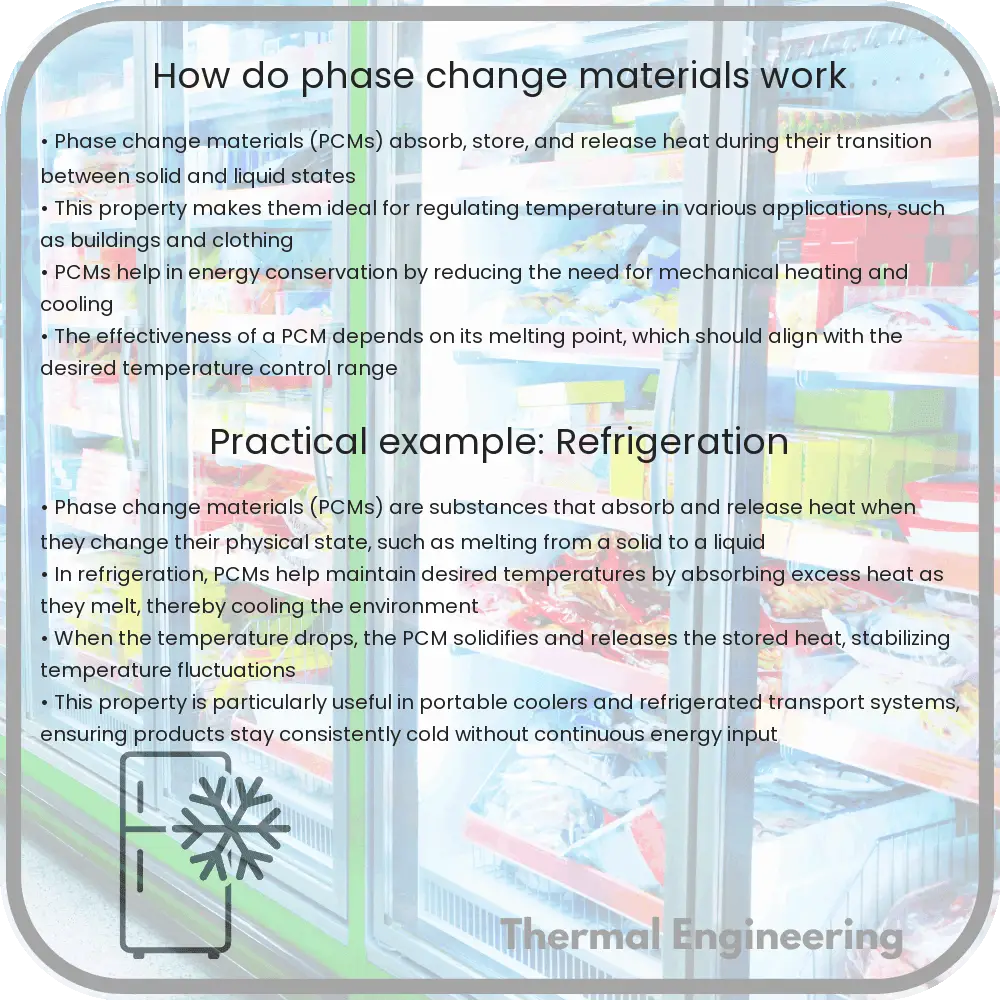

Phase Change Materials (PCMs) are substances that absorb and release thermal energy during the process of melting and freezing. They play a pivotal role in various applications ranging from building heating and cooling systems to renewable energy storage. PCMs operate on the simple principle of energy exchange through phase transition—primarily between solid and liquid states.

How Phase Change Materials Work

At the core of a PCM’s function is the latent heat of fusion—the energy absorbed or released during a change in state, with no change in temperature. When a PCM absorbs heat from its surroundings, it changes from a solid to a liquid, effectively storing this thermal energy in the form of latent heat. Conversely, when the environment cools, the PCM releases the stored heat as it returns to its solid state.

Key Types of Phase Change Materials

- Organic PCMs: These include materials like paraffin waxes and fatty acids. They are notable for their congruent melting, chemical stability, and minimal supercooling.

- Inorganic PCMs: Examples are salt hydrates and metallics which are characterized by higher latent heat per unit volume than organics but can suffer from phase separation and corrosion.

- Bio-based PCMs: These are extracted from agricultural resources and are both biodegradable and non-toxic, offering an environmentally friendly option.

Applications of Phase Change Materials

PCMs are utilized in a range of sectors to enhance efficiency and effectiveness in energy use:

- Thermal Energy Storage: In solar energy systems, PCMs store excess heat collected during peak sunshine hours, which is then used to heat homes or commercial buildings during the night or on cloudy days.

- Building Temperature Regulation: Incorporating PCMs in building materials, such as walls and floors, helps maintain a stable indoor environment, reducing the need for air conditioning and heating.

- Temperature Controlled Transport: PCMs are used in packaging for temperature-sensitive goods, such as pharmaceuticals and perishable foods, ensuring they maintain quality during transit.

Challenges and Future Opportunities

While PCMs offer notable advantages, they are not without their challenges. Key issues include cost-effectiveness, long-term reliability, and integration with existing systems. Future advancements are likely to focus on improving PCM composites for greater stability, expanding the range of temperatures in which they can effectively operate, and enhancing their overall sustainability.

In conclusion, Phase Change Materials present a fascinating and potent tool in the quest for efficient energy management. By harnessing the properties of these materials, scientists and engineers can significantly impact how thermal energy is utilized across various industries, potentially leading to more sustainable practices and innovations in temperature regulation technology.