Learn how heat impacts polymer degradation, affecting their mechanical properties and application reliability.

Understanding How Heat Affects the Degradation of Polymers

Polymers are a crucial part of everyday materials—from plastics in kitchenware to components in electronic devices. However, their properties can degrade over time and under various conditions, particularly heat. This degradation not only affects their performance but can also lead to failure in applications where reliability is critical. Understanding how heat impacts polymers can help in making better materials for heat-intensive environments.

Thermal Degradation of Polymers

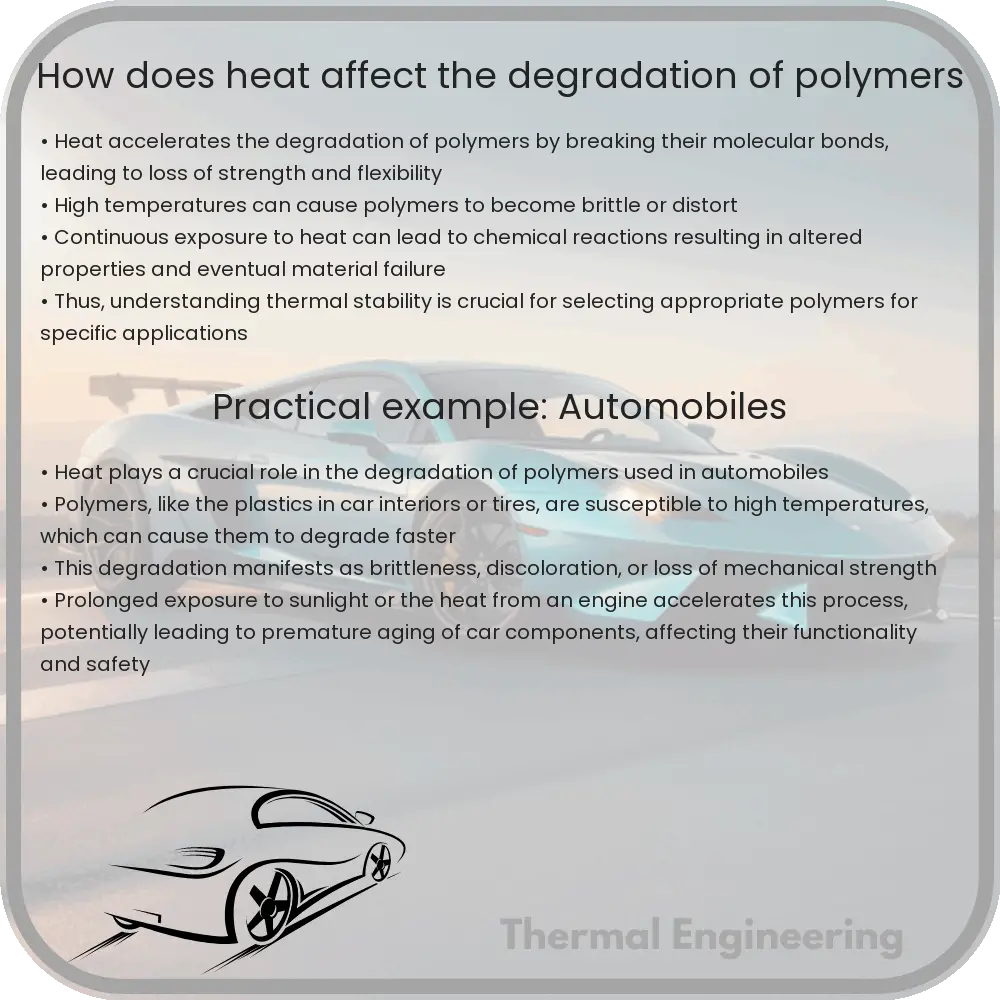

Thermal degradation of polymers is a chemical process where high temperatures cause the polymer chains to break down. This breakdown can result in reduced mechanical strength, discoloration, and ultimately, the failure of the material to perform its intended function. The degradation process is influenced by several factors, including the type of polymer, the presence of any additives, and environmental conditions.

Mechanisms of Heat-Induced Degradation

Two primary mechanisms through which heat affects the integrity of polymers are:

- Thermal Oxidation: When polymers are exposed to high temperatures in the presence of oxygen, oxidation reactions occur. These reactions lead to the formation of free radicals, which then propagate chain reactions that break down the polymer. This mechanism is significantly accelerated by increased temperatures.

- Chain Scission: High heat can cause the bonds within the polymer backbones to break, leading to chain scission. This process results in a decrease in molecular weight and deterioration of physical properties such as tensile strength and elasticity.

Factors Influencing Heat Degradation

Several factors determine the sensitivity of polymers to heat degradation:

- Structural Stability: Polymers with more stable structures, such as those with aromatic rings or cross-linking, generally have higher resistance to heat.

- Additives: Certain additives, like antioxidants and UV stabilizers, are used to enhance the thermal stability of polymers and slow down the degradation process.

- Environmental Conditions: The temperature, duration of exposure, and presence of oxygen play critical roles in the rate and extent of thermal degradation.

Measuring Thermal Degradation

The impact of heat on polymer degradation is typically assessed using techniques such as:

- Thermogravimetric Analysis (TGA): Measures changes in the mass of a polymer sample as it is heated, providing information on thermal stability and composition.

- Differential Scanning Calorimetry (DSC): Examines heat flows associated with thermal transitions in polymers to characterize events such as melting, crystallization, and oxidative stability.

Implications for Material Design and Engineering

The understanding of how heat affects polymer degradation is essential for the design of materials, particularly for those used in high-temperature environments like automotive or aerospace industries. Engineers can use this knowledge to select appropriate polymers, design components to mitigate thermal risks, and develop innovative materials with enhanced heat resistance.

In conclusion, while polymers are indispensable in numerous applications, their performance limitations under high heat are a significant challenge. Detailed knowledge of thermal degradation mechanisms, coupled with advanced analytical techniques, allows engineers and scientists to push the boundaries of polymer technology, creating materials that meet the demands of the future.