Delve into the workings of thermoelectric coolers, their heat management, applications, and the pros and cons of using Peltier effect-based technology.

Understanding Thermoelectric Coolers

Thermoelectric coolers (TECs), often referred to as Peltier coolers, are fascinating devices that facilitate heat transfer through electrical energy, relying on the Peltier effect. This solid-state method of cooling and heating has applications ranging from electronic devices to portable coolers. In this article, we’ll delve into the physics behind thermoelectric coolers, how they manage heat, and their advantages and limitations in practical applications.

The Principle of the Peltier Effect

The operation of thermoelectric coolers is based on the Peltier effect, which was discovered by French physicist Jean Charles Athanase Peltier in 1834. When electric current flows through a circuit of two different conductors, heating or cooling occurs at the junctions of the conductors. Specifically, heat is absorbed at one junction (cooling effect) and released at another junction (heating effect). This phenomenon is reversible by simply reversing the direction of the electrical current.

Composition of a Thermoelectric Cooler

A typical TEC consists of two ceramic plates with multiple p-type and n-type semiconductor elements between them. These semiconductors are usually made of bismuth telluride. The arrangement forms a series of thermocouples, which are connected electrically in series and thermally in parallel. When a DC voltage is applied, it drives a current through the thermocouples, creating a temperature difference between the two ceramic plates.

How TECs Manage Heat

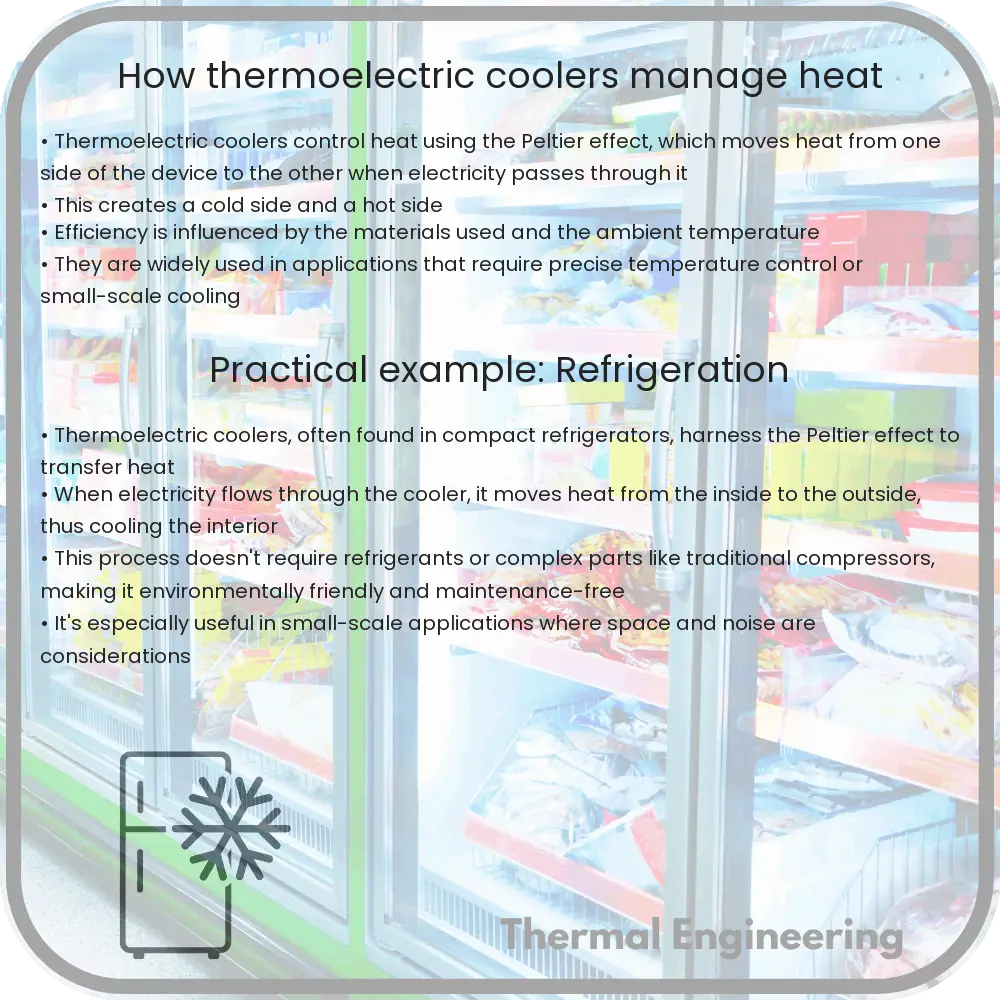

Managing heat efficiently is critical for the effective operation of thermoelectric coolers. The process can be outlined in several key steps:

- Cooling Process: When DC power is applied, electrons and holes in the semiconductor material move from one side to the other. This movement of charge carriers carries heat from one side of the cooler to the other, thus cooling one ceramic plate while heating the other.

- Heat Absorption: The cold side of the TEC absorbs heat from the environment or an object that needs to be cooled. This heat absorption continues as long as there is current flow and sufficient thermal insulation.

- Heat Dissipation: The hot side of the TEC dissipates heat into the environment. Typically, a heat sink is attached to the hot side to manage and disperse this heat efficiently, maintaining the performance of the cooler.

Applications of Thermoelectric Coolers

Thermoelectric coolers are used in a variety of applications, benefiting from their compact size and lack of moving parts. Some common applications include:

- Electronic components cooling

- Food and beverage refrigerators

- Temperature control in optical equipment

- Portable cooling systems for medical and scientific instruments

Advantages and Limitations

While TECs offer several advantages such as compactness, reliability due to the lack of moving parts, and precision in temperature control, they also have limitations:

- Efficiency: TECs generally have lower energy efficiency compared to traditional refrigeration methods, especially at larger scales.

- Heat Dissipation Needs: Effective heat dissipation systems are crucial, as the performance of a thermoelectric cooler depends heavily on its ability to expel excess heat.

- Cost: The cost of materials for high-efficiency thermoelectric materials can be high, impacting the overall cost-effectiveness of these systems.

In conclusion, thermoelectric coolers provide a unique and versatile method for controlling temperature in various applications. Understanding how they manage heat highlights both their capabilities and their limits, essential knowledge for anyone utilizing or designing systems based on this technology.