Learn about the vapor-compression refrigeration cycle, the most commonly used method in refrigerators and air conditioners for effective heat transfer.

Understanding the Vapor-Compression Refrigeration Cycle

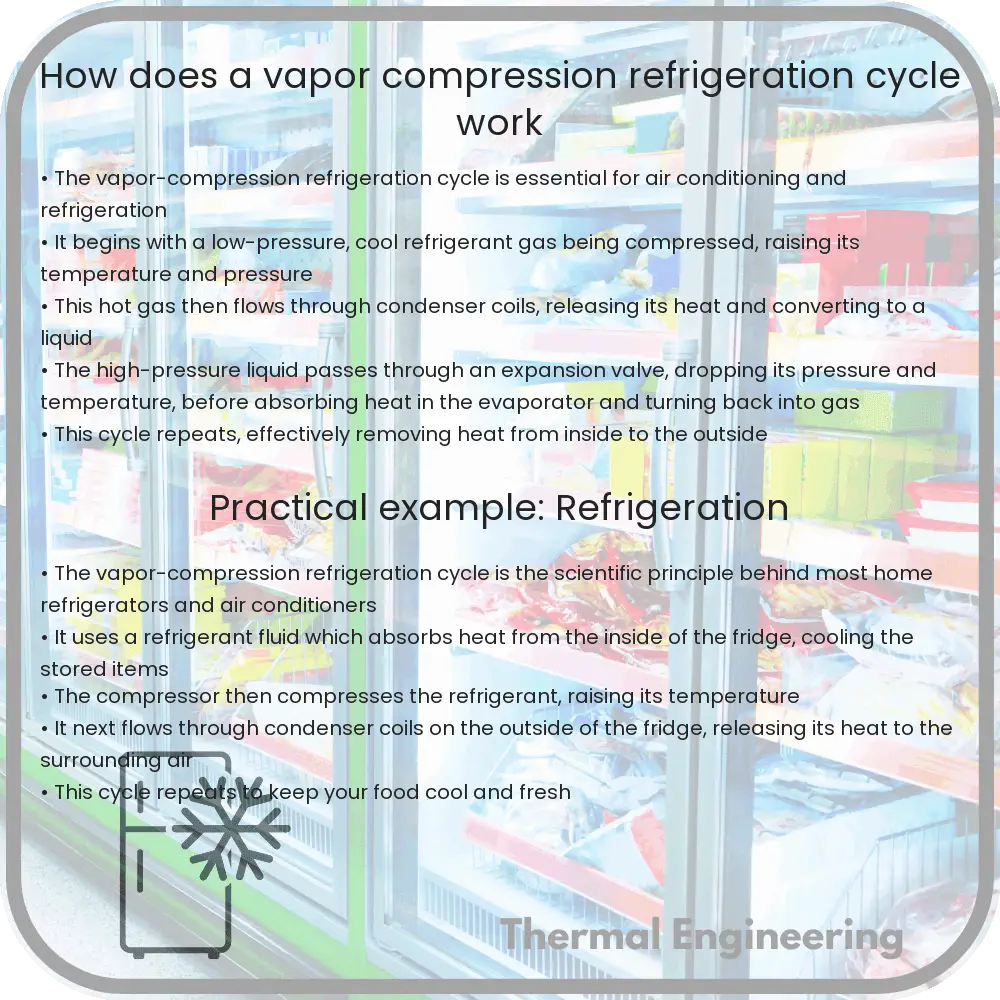

The vapor-compression refrigeration cycle is the most common method used in refrigerators, air conditioners, and heat pumps to transfer heat from one area to another. This process is vital for achieving controlled cooling and heating in various applications. Here, we will walkthrough the basic components and steps involved in a vapor-compression refrigeration cycle.

Key Components of the Cycle

- Evaporator: Absorbs heat from the environment or space to be cooled.

- Compressor: Pumps the refrigerant, raising its pressure and temperature.

- Condenser: Releases the absorbed heat to the outside environment.

- Expansion Valve: Lowers the pressure of the refrigerant, allowing it to expand and cool.

Steps in the Vapor-Compression Cycle

- Evaporation: The cycle begins in the evaporator, where the low-pressure liquid refrigerant absorbs heat from the surroundings. This heat converts the liquid into a gas.

- Compression: The refrigerant vapor is then compressed by the compressor. As the gas is compressed, its pressure and temperature both rise significantly. The refrigerant becomes a high-pressure hot vapor.

- Condensation: Next, this high-pressure hot vapor travels to the condenser. Here it releases its heat to the outside environment, condensing into a high-pressure liquid.

- Expansion: The high-pressure liquid then passes through the expansion valve, which reduces its pressure. This sudden reduction in pressure cools the liquid substantially, turning part of it into a low-pressure mixture of liquid and vapor, ready to absorb heat in the evaporator again.

Thermodynamics of the Cycle

The efficiency and effectiveness of the vapor-compression cycle depend largely on the principles of thermodynamics, particularly those relating to pressure, temperature, and phase changes of the refrigerant.

As the refrigerant undergoes these changes, it follows principles described by the First Law of Thermodynamics (conservation of energy) and the Second Law of Thermodynamics (increased entropy in heat transfer processes). The cycle is designed to optimize the boiling and condensation points of the refrigerant, exploiting its latent heat properties at various stages.

Equations concerning the energy input to the compressor (in terms of work done) and heat exchanged in the evaporator and condenser are crucial for understanding the energy dynamics within the cycle:

- Work done by compressor (W): W = m * (h2 – h1)

- Heat absorbed in evaporator (Qin): Qin = m * (h1 – h4)

- Heat rejected in condenser (Qout): Qout = m * (h2 – h3)

Here, m represents the mass flow rate of the refrigerant, and h denotes the specific enthalpy at various points in the cycle.

Applications and Importance

The vapor-compression cycle is fundamental in many modern technologies that require cooling and heating. It is essential for achieving desired temperature conditions in homes, offices, refrigerators, and industrial processes, demonstrating its vast importance in everyday life and various industrial applications.

Understanding this cycle not only helps in designing more efficient heating and cooling systems but also is crucial for advancing technologies that depend on precise temperature control, such as data center cooling and process manufacturing.

Conclusion

The vapor-compression refrigeration cycle demonstrates a classic example of applied thermodynamics in a practical, everyday system. By manipulating the pressure and temperature of a refrigerant, engineers can effectively control the heating and cooling in various devices, making this cycle a cornerstone of modern refrigeration and air conditioning technology.