Critical Power Ratio – Dryout

In BWRs, similar phenomenon is known as “dryout” and it is directly associated with changes in flow pattern during evaporation in the high-quality region. At given combinations of flow rate through a channel, pressure, flow quality, and linear heat rate, the wall liquid film may exhaust and the wall may be dried out. At normal, the fuel surface is effectively cooled by boiling coolant. However when the heat flux exceeds a critical value (CHF – critical heat flux) the flow pattern may reach the dryout conditions (thin film of liquid disappears). The heat transfer from the fuel surface into the coolant is deteriorated, with the result of a drastically increased fuel surface temperature. In the high-quality region, the crisis occurs at a lower heat flux. Since the flow velocity in the vapor core is high, post-CHF heat transfer is much better than for low-quality critical flux (i.e. for PWRs temperature rises are higher and more rapid).

In BWRs, similar phenomenon is known as “dryout” and it is directly associated with changes in flow pattern during evaporation in the high-quality region. At given combinations of flow rate through a channel, pressure, flow quality, and linear heat rate, the wall liquid film may exhaust and the wall may be dried out. At normal, the fuel surface is effectively cooled by boiling coolant. However when the heat flux exceeds a critical value (CHF – critical heat flux) the flow pattern may reach the dryout conditions (thin film of liquid disappears). The heat transfer from the fuel surface into the coolant is deteriorated, with the result of a drastically increased fuel surface temperature. In the high-quality region, the crisis occurs at a lower heat flux. Since the flow velocity in the vapor core is high, post-CHF heat transfer is much better than for low-quality critical flux (i.e. for PWRs temperature rises are higher and more rapid).

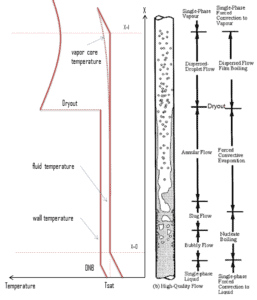

Typical flow boiling modes in a vertical channel are depicted in the figure. This figure shows the typical order of the flow regimes that are encountered from inlet to outlet of a heated channel. At the inlet, the liquid enters subcooled (at the lower temperature than saturation). In this region the flow is single-phase. As the liquid heats up, the wall temperature correspondingly rises. As the wall temperature exceeds the saturation temperature (e.g. 285°C at 6.8 MPa), subcooled nucleate boiling begins. Bubbles nucleate in the superheated thermal boundary layer on the heated wall but tend to condense in the subcooled bulk.

Further increase in liquid temperature causes, that the liquid bulk reaches its saturation temperature and the convective boiling process passes through the bubbly flow into the slug flow. Increasing void fraction causes that the structure of the flow becomes unstable. The boiling process passes through the slug and churn flow into the annular flow regime with its characteristic annular film of the liquid. At given combinations of flow rate through a channel, pressure, flow quality, and linear heat rate, the wall liquid film may exhaust and the wall may be dried out. At the dryout point the wall temperature significantly rises in order to dissipate the applied heat flux. The post-dryout flow (mist or drop flow) in the heated channel is undesirable, because the presence of such flow regime is accompanied with significantly higher wall temperatures and high fluctuation of wall temperatures.

In this case, engineers define parameter known as the minimum critical power ratio (MCPR) instead of DNBR. The critical power ratio (CPR) is used for determining the thermal limits of boiling water reactors.

Definition of CPR :

The CPR is that power in the assembly that is calculated by application of the appropriate correlation(s) to cause some point in the assembly to experience boiling transition, divided by the actual assembly operating power.

Special Reference: Tong, L. S., Weisman, Joel. Thermal Analysis of Pressurized Water Reactors. Amer Nuclear Society, 3rd edition, 5/1996. ISBN-13: 978-0894480386.

We hope, this article, Dryout – Critical Power Ratio, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.