Thermal Contact Resistance – Thermal Contact Conductance

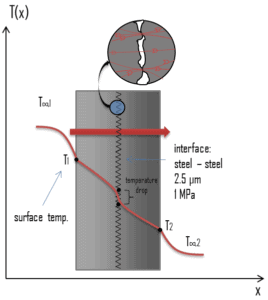

In thermal engineering, the thermal contact conductance [W/m2.K] or thermal contact resistance [m2.K/W] represents the heat conduction between two solid bodies. When components are bolted or otherwise pressed together, a knowledge of the thermal performance of such joints are also needed. In these composite systems, the temperature drop across the interface between materials may be appreciable. This temperature drop is characterized by the thermal contact conductance coefficient, hc, which is a property indicating the thermal conductivity, or ability to conduct heat, between two bodies in contact. While extensive databases exist on the thermal properties of bulk materials, similar databases for pressed contacts do not.

In thermal engineering, the thermal contact conductance [W/m2.K] or thermal contact resistance [m2.K/W] represents the heat conduction between two solid bodies. When components are bolted or otherwise pressed together, a knowledge of the thermal performance of such joints are also needed. In these composite systems, the temperature drop across the interface between materials may be appreciable. This temperature drop is characterized by the thermal contact conductance coefficient, hc, which is a property indicating the thermal conductivity, or ability to conduct heat, between two bodies in contact. While extensive databases exist on the thermal properties of bulk materials, similar databases for pressed contacts do not.

The inverse of this property is termed thermal contact resistance.

The contact resistance depends on the surface roughness to a great extent. The pressure holding the two surfaces together also influences the contact resistance. Thermal contact resistance is observed to decrease with decreasing surface roughness and increasing interface pressure. This is attributed to the fact that the contact surface between the bodies grows as the contact pressure grows. When two such surfaces are pressed against each other, the peaks will form good material contact but the valleys will form voids filled with air. These voids filled with air act as insulation because of the low thermal conductivity of air. The limited number and size of the contact spots results in an actual contact area which is significantly smaller than the apparent contact area. In case of metallic composite material, which is placed in a vacuum, thermal conduction through the contact spots is the primary mode of heat transfer, and the contact resistance is generally greater than when the composite material is in the presence of air or other fluid. Moreover, thermal contact resistance is significant and may dominate for good heat conductors such as metals but can be neglected for poor heat conductors such as insulators.

For example:

- The thermal contact conductance for aluminum plates with a surface roughness of 10 μm placed in air with the interface pressure of 1 atm is hc = 3640 W/m2.K

- The thermal contact conductance for aluminum plates with a surface roughness of 10 μm placed in helium with the interface pressure of 1 atm is hc = 9520 W/m2.K

- The thermal contact conductance for stainless steel plates with a surface roughness of 2.5 μm placed in air with the interface pressure of 1 MPa is about hc = 3000 W/m2.K

The thermal contact resistance can be minimized by applying a thermally conducting liquid called a thermal grease such as CPU grease on the surfaces before they are pressed against each other. The main role of thermal grease is to eliminate air gaps or spaces (which act as thermal insulator) from the interface area so as to maximize heat transfer. The thermal conductivity of the interstitial material and its pressure are the two properties governing its influence on contact conductance.

Special Reference: Madhusudana, Chakravarti V., Thermal Contact Conductance. Springer International Publishing, 2014. ISBN: 978-3-319-01276-6.

We hope, this article, Thermal Contact Resistance – Thermal Contact Conductance, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.