Brayton Cycle with Reheat, Regeneration and Intercooling

Reheat, Intercooling and Regeneration in Brayton Cycle

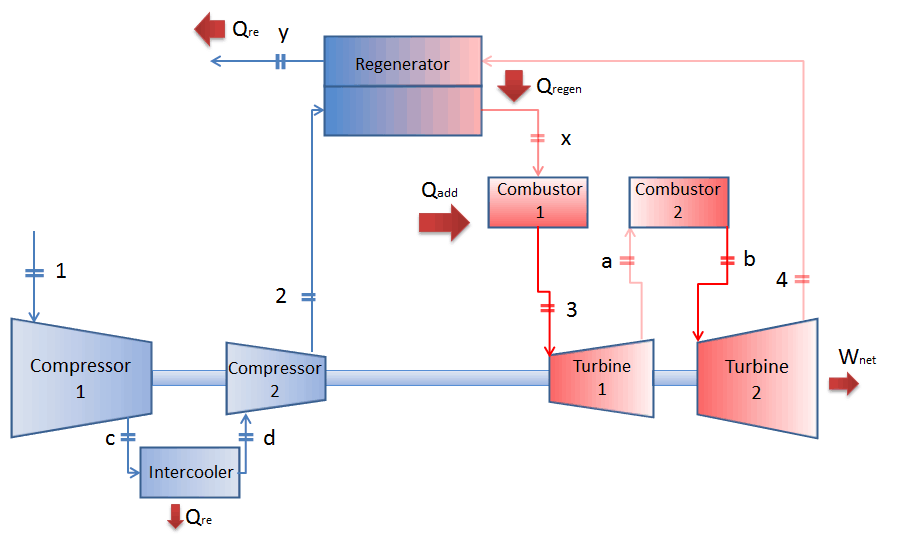

As was discussed reheat and intercooling are complementary with heat regeneration. By itself, they would not necessarily increase the thermal efficiency, however, when intercooling or reheat is used in conjunction with heat regeneration, a significant increase in thermal efficiency can be achieved and the net work output is also increased. This requires a gas turbine with two stages of compression and two turbine stages.

The second Ericsson cycle is similar to the Brayton cycle, but uses external heat and incorporates the multiple use of an intercooling and reheat. In fact, it is like a Brayton cycle with an infinite number of reheat and intercooler stages in the cycle. Compared to the Brayton cycle which uses adiabatic compression and expansion, an ideal Ericsson cycle consists of isothermal compression and expansion processes, combined with isobaric heat regeneration between them. Applying intercooling, heat regeneration and sequential combustion significantly increases thermal efficiency of a turbine, in fact, the thermal efficiency of the ideal Ericsson cycle equals to the Carnot efficiency.

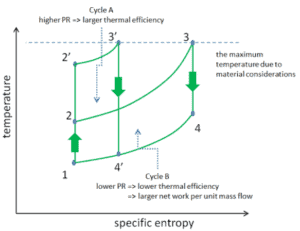

Thermal Efficiency Improvement – Brayton Cycle

There are several methods, how can be the thermal efficiency of the Brayton cycle improved. Assuming that the maximum temperature is limited by metallurgical consideration, these methods are:

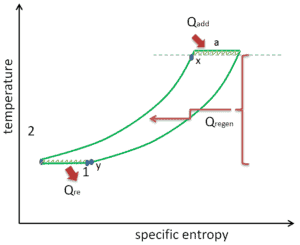

As was discussed, increasing the pressure ratio increases the compressor discharge temperature. Since the turbine inlet temperature is limited by the maximum temperature that the turbine blades can withstand, the pressure ration influences the heat amount that can be added to the flow. Moreover with an increase of the pressure ratio, the diameter of the compressor blades becomes progressively smaller in higher pressure stages of the compressor. Because the gap between the blades and the engine casing increases in size as a percentage of the compressor blade height as the blades get smaller in diameter, a greater percentage of the compressed air can leak back past the blades in higher pressure stages. This causes a leak back and in result it decreases the isentropic compressor efficiency (will be discussed later). Finally, from the formula for the thermal efficiency in term of pressure ratio can be seen, there is smaller gain as the pressure ratio increases (due to the exponent).

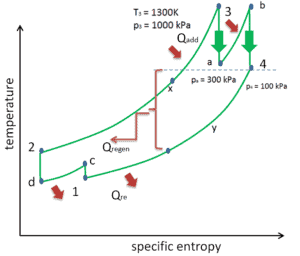

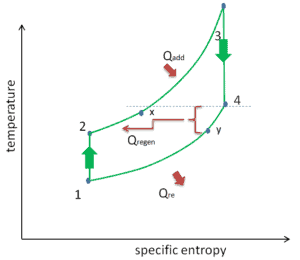

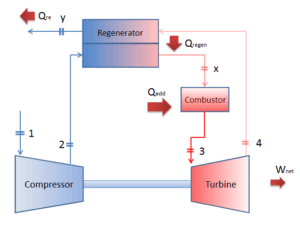

Significant increases in the thermal efficiency of gas turbine power plants can be achieved through reducing the amount of fuel that must be burned in the combustion chamber. This can be done by transferring heat from the turbine exhaust gas, which is normally well above the ambient temperature, to the compressor discharge air flow known as heat regeneration. Especially at a low or moderate pressure ratio, there is a high temperature increase in the combustion chamber and the turbine exhaust gas might still contain significant amount of heat at higher temperature than the compressor outlet gas (after the last compression stage but before the combustor). For this purpose a heat exchanger called a regenerator is used. Sometimes engineers use the term economiser that are heat exchangers intended to reduce energy consumption, especially in case of preheating of a fluid.

This heat regenerator allows the air exiting the compressor to be preheated before it enters the combustion chamber, thereby reducing the amount of fuel that must be burned in the combustor. This form of heat recycling is only possible if the gas turbine is run with low pressure ratio.

As was stated the temperature difference between turbine outlet and compressor outlet is crucial and determines the amount of heat that can be recovered. In case of negative difference (i.e. T2 > T4), the heat regeneration is not possible. There are two main ways, how to change this difference:

- to increase the turbine outlet temperature (T4) through reheat of the flow during expansion phase (i.e. use of a multistage turbine with a reheat combustor or with a reheater)

- to decrease the compressor outlet temperature (T2) through intercooling of the flow during compression phase (i.e. use of a multistage compressor with an intercooler)

Therefore reheat and intercooling are complementary with heat regeneration. By itself, they would not necessarily increase the thermal efficiency, however, when intercooling or reheat is used in conjunction with heat regeneration, a significant increase in thermal efficiency can be achieved.

It must be noted, transferring heat from the turbine outlet to the compressor inlet would reduce efficiency, as hotter inlet air means more volume, thus more work for the compressor. Engineers must also take into consideration pressure losses generated by the heat exchanger that slightly reduce the power of the gas turbine.

Regeneration vs. Recuperation of Heat

In general, the heat exchangers used in regeneration may be classified as either regenerators or recuperators.

- Regenerator is a type of heat exchanger where heat from the hot fluid is intermittently stored in a thermal storage medium before it is transferred to the cold fluid. It has a single flow path in which the hot and cold fluids alternately pass through.

- Recuperator is a type of heat exchanger has separate flow paths for each fluid along their own passages and heat is transferred through the separating walls. Recuperators (e.g. economisers) are often used in power engineering, to increase the overall efficiency of thermodynamic cycles. For example, in a gas turbine engine. The recuperator transfers some of the waste heat in the exhaust to the compressed air, thus preheating it before entering the combustion chamber. Many recuperators are designed as counterflow heat exchangers.

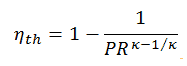

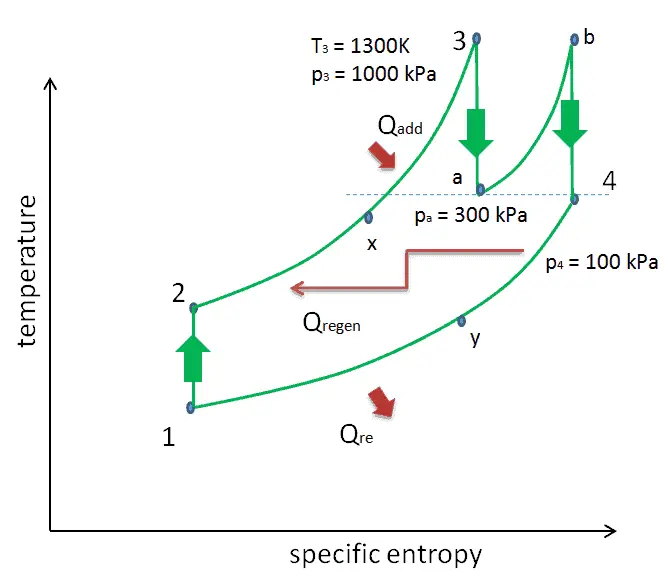

As was discussed, the maximum temperature is limited by metallurgical consideration, but in order to deliver more of the heat at a temperature close to the peak of the cycle the gas can be reheated in a reheater. This involves splitting the turbine, i.e. use of a multistage turbine with a reheat combustor or with a reheater. High pressure and low pressure stages of the turbine may be on the same shaft to drive a common generator, but they will have separate cases. With a reheater, the flow is extracted after a partial expansion (point a), run back through the heat exchanger to heat it back up to the peak temperature (point b), and then passed to the lower pressure stage of the turbine. The expansion then completed in this stage from point b to point 4.

With this arrangement the net work per unit of mass flow can be increased. Despite the increase in net work with reheat, the cycle thermal efficiency would not necessarily increase because a greater total heat addition would be required. On the other hand, the temperature at the exit of the turbine (low pressure stage) is higher with reheat than without reheat, so there is the potential for heat regeneration. Therefore reheat and regeneration are complementary, they are used usually together in order to increase the thermal efficiency of gas turbine.

Significant increases in the thermal efficiency of gas turbine power plants can be achieved also through intercooling. Intercooling can be applied between compressor stages to reduce compression work, WC, hence increasing overall power of the gas turbine.

For this purpose a heat exchanger known as an intercooler is usually used between stages of a multi-stage compression process. In general, intercoolers are heat exchangers that are used in many applications, including air compressors, air conditioners, refrigerators, and gas turbines. Intercoolers are widely known also in automotive use as a turbocharger or supercharger, but here they increase intake air charge density, hence the power of an engine.

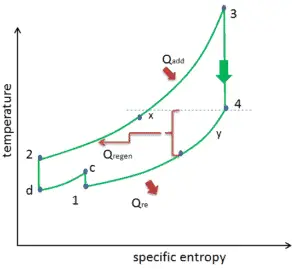

In gas turbine power plant the thermal efficiency is of the highest importance and intercooling with heat regeneration are widely used. This involves splitting the compressor, i.e. use of a multistage compressor with an intercooler or intercoolers. High pressure and low pressure stages of the compressor may be on the same shaft even with turbine or a generator, but it is not a rule. With an intercooler, the flow is extracted after a partial compression (point c), run through the heat exchanger (intercooler) to cool it to the ambient temperature (point d), and then passed to the high stage of compressor. The compression is then completed in the second compressor from point d to point 2.

With this arrangement the net work per unit of mass flow (↑Wnet = WT – ↓WC) can be increased by reducing the compression work (↓WC). Despite the increase in net work with intercooling, the cycle thermal efficiency would not necessarily increase because the temperature of the air entering the combustor would be reduced and a greater total heat addition would be required to achieve the desired turbine inlet temperature. On the other hand, the temperature at the exit of the compressor (high pressure stage) is lower with intercooling than without intercooling, so there is the potential for heat regeneration (Qregen increases). Note that, the heat regeneration requires lower compressor outlet temperature than the turbine outlet temperature (simply due to 2nd law) and this temperature difference determines the amount of heat available for heat regeneration.

Therefore reheat and intercooling are complementary with heat regeneration. By itself, they would not necessarily increase the thermal efficiency, however, when intercooling or reheat is used in conjunction with heat regeneration, a significant increase in thermal efficiency can be achieved.

Some large compressors with higher pressure ratio have several stages of compression with intercooling between stages. Engineers must also take into consideration pressure losses generated by all heat exchangers that slightly increase compression work. The certain gas turbine design (the number of intercoolers, reheaters and regenerators) is an engineering problem and depends on certain purpose of the gas turbine.

- J. R. Lamarsh, Introduction to Nuclear Reactor Theory, 2nd ed., Addison-Wesley, Reading, MA (1983).

- J. R. Lamarsh, A. J. Baratta, Introduction to Nuclear Engineering, 3d ed., Prentice-Hall, 2001, ISBN: 0-201-82498-1.

- W. M. Stacey, Nuclear Reactor Physics, John Wiley & Sons, 2001, ISBN: 0- 471-39127-1.

- Glasstone, Sesonske. Nuclear Reactor Engineering: Reactor Systems Engineering, Springer; 4th edition, 1994, ISBN: 978-0412985317

- W.S.C. Williams. Nuclear and Particle Physics. Clarendon Press; 1 edition, 1991, ISBN: 978-0198520467

- Kenneth S. Krane. Introductory Nuclear Physics, 3rd Edition, Wiley, 1987, ISBN: 978-0471805533

- G.R.Keepin. Physics of Nuclear Kinetics. Addison-Wesley Pub. Co; 1st edition, 1965

- Robert Reed Burn, Introduction to Nuclear Reactor Operation, 1988.

- U.S. Department of Energy, Nuclear Physics and Reactor Theory. DOE Fundamentals Handbook, Volume 1 and 2. January 1993.

Advanced Reactor Physics:

- K. O. Ott, W. A. Bezella, Introductory Nuclear Reactor Statics, American Nuclear Society, Revised edition (1989), 1989, ISBN: 0-894-48033-2.

- K. O. Ott, R. J. Neuhold, Introductory Nuclear Reactor Dynamics, American Nuclear Society, 1985, ISBN: 0-894-48029-4.

- D. L. Hetrick, Dynamics of Nuclear Reactors, American Nuclear Society, 1993, ISBN: 0-894-48453-2.

- E. E. Lewis, W. F. Miller, Computational Methods of Neutron Transport, American Nuclear Society, 1993, ISBN: 0-894-48452-4.

Other References:

We hope, this article, Brayton Cycle with Reheat, Regeneration and Intercooling, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.