HP Turbine – High-pressure Steam Turbine

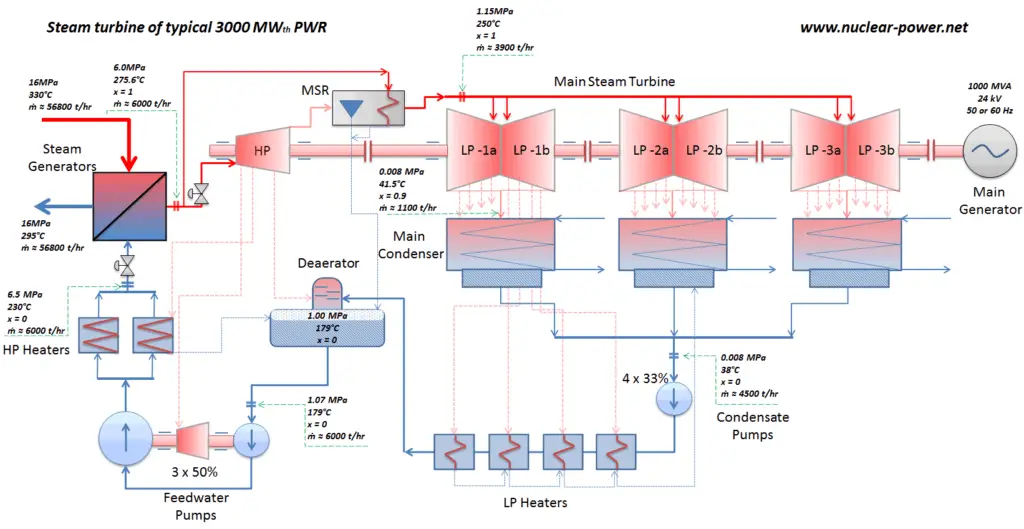

Most of nuclear power plants operates a single-shaft turbine-generator that consists of one multi-stage HP turbine and three parallel multi-stage LP turbines, a main generator and an exciter.

HP Turbine (high-pressure turbine) is usually double-flow turbine element with an impulse control stage followed by reaction blading in each end of the element. There are about 10 stages with shrouded blades in the HP turbine. It the produces about 30-40% of the gross power output of the power plant unit.

HP turbine is equipped usually with 3 or 4 self-regulating extraction lines, which are used to provide steam for:

- the deaerator

- the high pressure feedwater heaters

- the feedwater pumps (when driven by steam turbines)

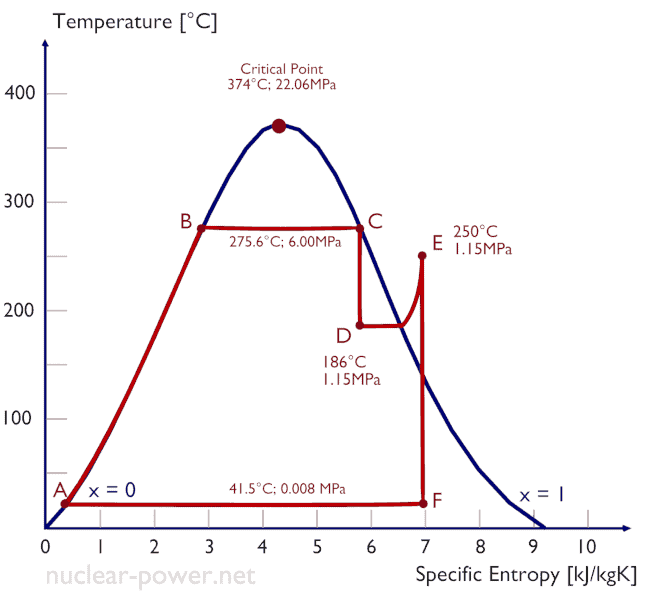

In HP turbine the high-pressure stage receives steam (this steam is nearly saturated steam – x = 0.995 – point C at the figure; 6 MPa; 275.6°C) from a steam generator and exhaust it to moisture separator-reheater (MSR – point D – ~1.15 MPa; ~186°C; x ≈ 0.9). The steam must be reheated in order to avoid damages that could be caused to blades of steam turbine by low quality steam. High content of water droplets can cause the rapid impingement and erosion of the blades which occurs when condensed water is blasted onto the blades. The reheater heats the steam (point D) and then the steam is directed to the low-pressure stage of steam turbine, where expands (point E to F).

We hope, this article, HP Turbine – High-pressure Steam Turbine, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.