Impulse Turbine and Reaction Turbine

Steam turbines may be classified into different categories depending on their construction, working pressures, size and many other parameters. But there are two basic types of steam turbines:

- impulse turbines

- reaction turbines.

The main distinction is the manner in which the steam is expanded as it passes through the turbine.

Impulse Turbine and Reaction Turbine

Steam turbine types based on blade geometry and energy conversion process are impulse turbine and reaction turbine.

Impulse Turbine

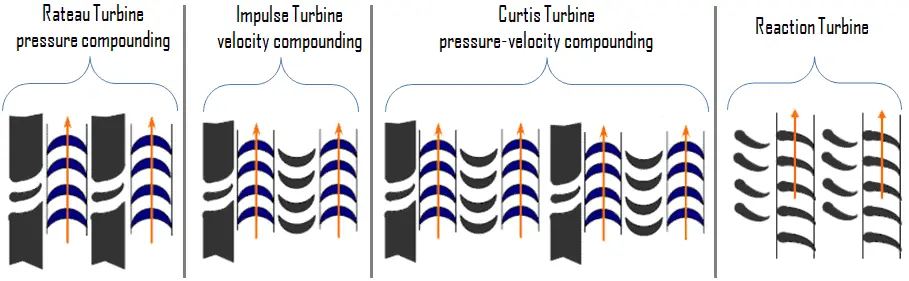

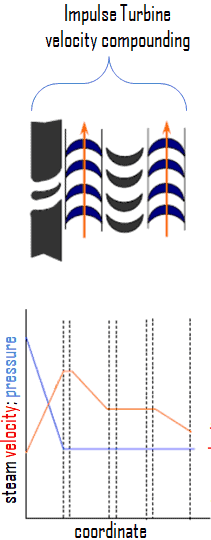

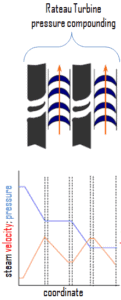

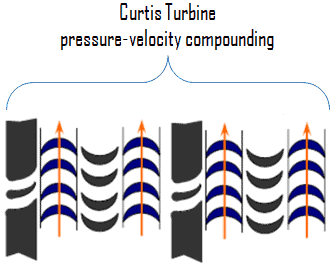

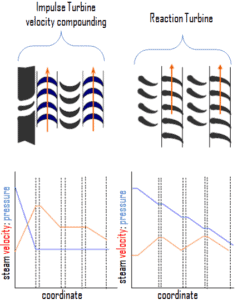

The impulse turbine is composed of moving blades alternating with fixed nozzles. In the impulse turbine, the steam is expanded in fixed nozzles and remains at constant pressure when passing over the blades. Curtis turbine, Rateau turbine, or Brown-Curtis turbine are impulse type turbines. The original steam turbine, the De Laval, was an impulse turbine having a single-blade wheel.

The impulse turbine is composed of moving blades alternating with fixed nozzles. In the impulse turbine, the steam is expanded in fixed nozzles and remains at constant pressure when passing over the blades. Curtis turbine, Rateau turbine, or Brown-Curtis turbine are impulse type turbines. The original steam turbine, the De Laval, was an impulse turbine having a single-blade wheel.

The entire pressure drop of steam take place in stationary nozzles only. Though the theoretical impulse blades have zero pressure drop in the moving blades, practically, for the flow to take place across the moving blades, there must be a small pressure drop across the moving blades also.

In impulse turbines, the steam expands through the nozzle, where most of the pressure potential energy is converted to kinetic energy. The high-velocity steam from fixed nozzles impacts the blades, changes its direction, which in turn applies a force. The resulting impulse drives the blades forward, causing the rotor to turn. The main feature of these turbines is that the pressure drop per single stage can be quite large, allowing for large blades and a smaller number of stages. Except for low-power applications, turbine blades are arranged in multiple stages in series, called compounding, which greatly improves efficiency at low speeds.

Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. The rotor blades are usually designed like an impulse blade at the rot and like a reaction blade at the tip.

Since the Curtis stages reduce significantly the pressure and temperature of the fluid to a moderate level with a high proportion of work per stage. An usual arrangement is to provide on the high pressure side one or more Curtis stages, followed by Rateau or reaction staging. In general, when friction is taken into account reaction stages the reaction stage is found to be the most efficient, followed by Rateau and Curtis in that order. Frictional losses are significant for Curtis stages, since these are proportional to steam velocity squared. The reason that frictional losses are less significant in the reaction stage lies in the fact that the steam expands continuously and therefore flow velocities are lower.

Reaction Turbine – Parsons Turbine

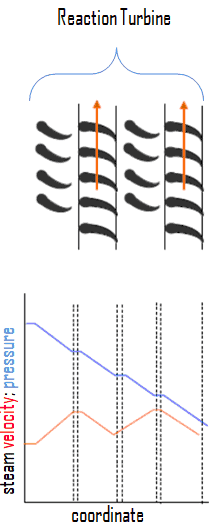

In reaction turbines, the steam expands through the fixed nozzle , where the pressure potential energy is converted to kinetic energy. The high-velocity steam from fixed nozzles impacts the blades (nozzles), changes its direction and undergo further expansion. The change in its direction and the steam acceleration applies a force. The resulting impulse drives the blades forward, causing the rotor to turn. Ther is no net change in steam velocity across the stage but with a decrease in both pressure and temperature, reflecting the work performed in the driving of the rotor. In this type of turbine the pressure drops take place in a number of stages, because the pressure drop in a single stage is limited.

The main feature of this type of turbine is that in contrast to the impulse turbine, the pressure drop per stage is lower, so the blades become smaller and the number of stages increases. On the other hand, reaction turbines are usually more efficient, i.e. they have higher “isentropic turbine efficiency”. The reaction turbine was invented by Sir Charles Parsons and is known as the Parsons turbine.

In the case of steam turbines, such as would be used for electricity generation, a reaction turbine would require approximately double the number of blade rows as an impulse turbine, for the same degree of thermal energy conversion. Whilst this makes the reaction turbine much longer and heavier, the overall efficiency of a reaction turbine is slightly higher than the equivalent impulse turbine for the same thermal energy conversion.

Modern steam turbines frequently employ both reaction and impulse in the same unit, typically varying the degree of reaction and impulse from the blade root to its periphery. The rotor blades are usually designed like an impulse blade at the rot and like a reaction blade at the tip.

We hope, this article, Impulse Turbine and Reaction Turbine, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.