Turbine Bypass System – Turbine Steam Dump System

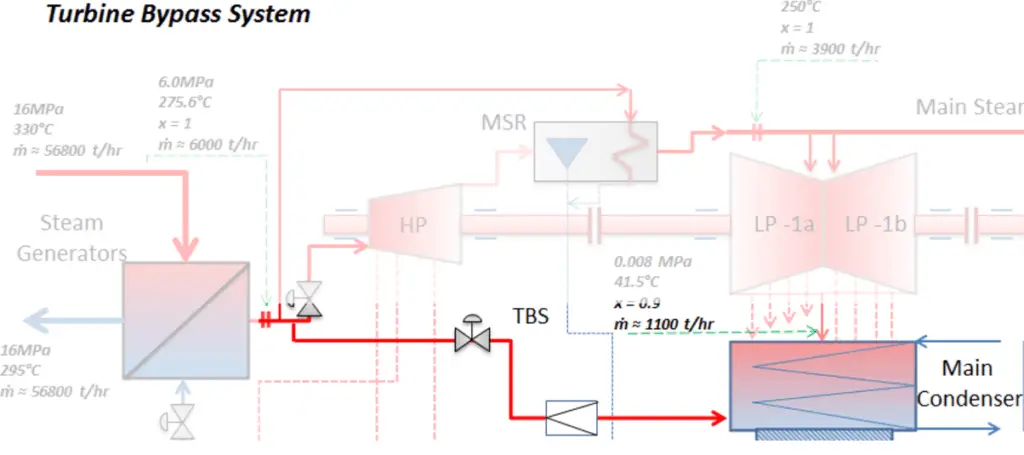

The turbine bypass system (TBS) or the turbine steam dump system provides operational flexibility so that the plant may accept certain load changes without disturbing the nuclear steam supply system (NSSS). The function of the turbine bypass system is to remove excess energy from the reactor coolant system by discharging a stated percentage of rated main steam flow directly to the main condensers, i.e. by bypassing the turbine. This heat is rejected to the condenser through the steam dump valves. The capacity of the system depends upon certain plant design, but it may be around 40 – 50% of nominal steam production. The steam dump valves automatically open under a sudden reduction in turbine-generator load or a turbine trip, which causes an increase in the system pressure.

In fact, the turbine bypass system usually corrects the system pressure of the power conversion unit. For example, during a turbine load reduction (e.g. caused by failure of 1/3 condensate pumps), the automatic reactor control system cannot reduce reactor thermal power as fast as the turbine power must decrease. Under these conditions, a power imbalance (NSSS / Turbine-Generator) results, with reactor power greater than the secondary system load (i.e. more heat is being added to the reactor coolant than that removed by the secondary via the steam generators). This power imbalance causes the pressure inside the steam generators to increase, which results in an increase in the temperature of the reactor coolant. Since the core inlet temperature is limited, the turbine bypass system is designed to establish the balance between the primary circuit and the secondary circuit, which limits this unwanted temperature increase.

The TBS is not a safety system, because it is not required for safe shutdown, as the relief and safety valves are operated under emergency conditions. The turbine bypass system is not required to function as a heat sink for the prevention or mitigation of postulated accidents. Failure of the TBS during a load reduction or turbine trip would result in the actuation of the relief valves and possibly the safety valves.

The turbine bypass system is also used in the pressure control mode during plant cooldown, plant heatup and plant startup. For example, prior to synchronizing the generator to the grid, the reactor must be operated in the “power mode” (e.g. at 30% of rated power), while the steam production is bypassed to the condenser. The turbine bypass valves close automatically as steam is admitted to the turbine.

We hope, this article, Turbine Bypass System – Turbine Steam Dump System, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.