Cavitation in Centrifugal Pumps

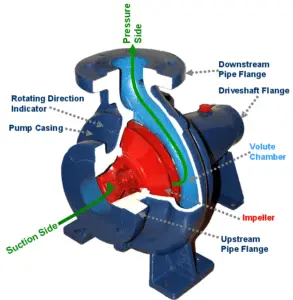

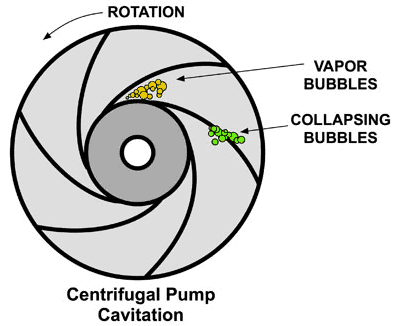

Major places where cavitation occurs are in pumps, on impellers or propellers. In centrifugal pumps, cavitation results from a reduction in suction pressure, an increase in suction temperature, or an increase in the flow rate above that for which the pump has been designed.

Major places where cavitation occurs are in pumps, on impellers or propellers. In centrifugal pumps, cavitation results from a reduction in suction pressure, an increase in suction temperature, or an increase in the flow rate above that for which the pump has been designed.

There are two basic types of pump cavitation:

Suction Cavitation

Typical causes of suction cavitation:

- Pump is running too far right on the pump curve

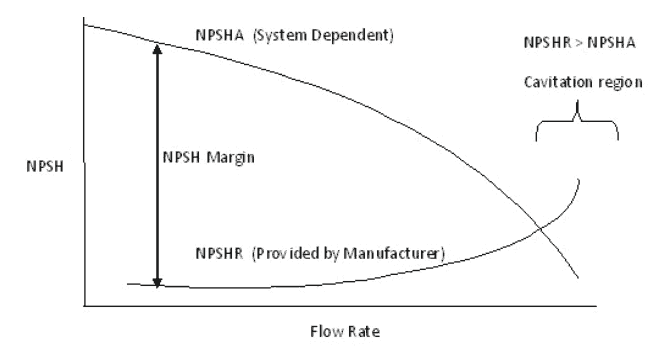

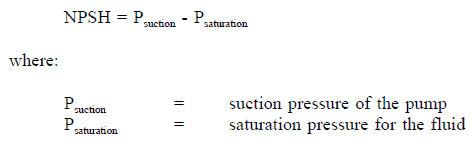

- Poor suction conditions (NPSH requirements)

- Blockage in the pipe on suction side

- Inappropriate piping design

- Clogged filters or strainers

To prevent this type of cavitation, the Net Positive Suction Head available (NPSHa) in the system must be higher than the required NPSH of the pump. This problem is typical for suction cavitation and therefore this type of cavitation is also called inadequate NPSHa cavitation.

Besides the change of the pump, problems with suction cavitation can be also solved by:

- Lowering the temperature

- Reduction of motor RPM if possible

- Increase of the diameter of the eye of the impeller

- Use of an impeller inducer.

- Use of two parallel pumps with lower capacity.

- Use of a booster pump to feed the principal pump.

Special case of cavitation occurs at the suction side as a result of inappropriate piping in suction line. Use of restrictions, sharp elbows and other hydraulic equipment can turbulize the flow this can contribute to cavitation formation.

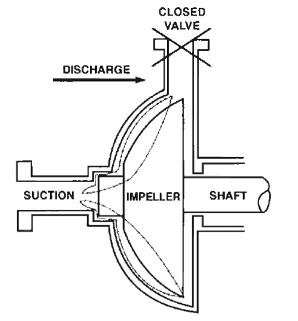

Discharge Cavitation

This type of cavitation originates from two sources. First, this internal circulation (from high-pressure zones into low-pressure zones) is forced through the clearance between the impeller and the pump housing at high velocity resulting in the formation of a low pressure region (as a result of Bernoulli’s principle) in which cavitation can occur. Second, the liquid is circulating inside the volute of the pump and it rapidly overheats.

In both cases, cavitation have similar consequences. The implosion of bubbles trigger intense shockwaves, causing premature wear of the impeller tips and pump housing. In extreme case, discharge cavitation can cause the impeller shaft to break.

Typical causes of discharge cavitation:

- Pump is running too far left on the pump curve

- Blockage in the pipe on discharge side

- Clogged filters or strainers

- Inappropriate piping design

Cavitation Number

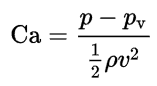

The Cavitation Number (Ca) or Cavitation Parameter is a dimensionless number used in flow calculations. It is conventional to characterize how close the pressure in the liquid flow is to the vapor pressure (and therefore the potential for cavitation) by means of the cavitation number.

The Cavitation Number can be expressed as:

where

CA = Cavitation Number

p = local pressure (Pa)

pv = vapor pressure of the fluid (Pa)

ρ = density of the fluid (kg/m3)

v = velocity of fluid (m/s)

Cavitation Damage

Cavitation is, in many cases, an undesirable occurrence. In centrifugal pumps, cavitation causes damage to components (erosion of the material), vibrations, noise and a loss of efficiency.

https://commons.wikimedia.org/wiki/File:Turbine_Francis_Worn.JPG

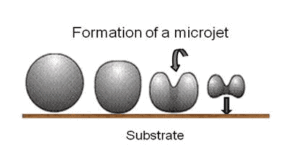

Perhaps the most important engineering problem caused by cavitation is the material damage that cavitation bubbles can cause when they collapse in the vicinity of a solid surface. Cavitation bubbles collapse is a violent process that generates highly localized shock waves and microjets. They force energetic liquid into very small volumes, thereby creating spots of high temperature and these intense disturbances generate highly localized and transient surface stresses to a solid surface. Signs of erosion will appear as pitting due to the waterhammering action of the collapsing vapour bubbles. It has been found that cavitation damage rates increase rapidly with the increase in the volume flow rate.

Softer materials can be damaged even by short-term occurrance of cavitation. Individual pits can be observed after a single bubble collapse. Therefore harder materials are used for centrifugal pumps. But with the harder materials used in most applications, the cyclic stress due to repeated collapses can cause local surface fatigue failure. Thus cavitation damage to metals usually has the appearance of fatigue failure.

When the cavitation bubbles collapse, they force energetic liquid into very small volumes, thereby creating spots of high temperature and emitting shock waves, the latter of which are a source of noise. Although the collapse of a small cavity is a relatively low-energy event, highly localized collapses can erode metals, such as steel, over time. The pitting caused by the collapse of cavities produces great wear on components and can dramatically shorten a propeller or pump’s lifetime.

When the cavitation bubbles collapse, they force energetic liquid into very small volumes, thereby creating spots of high temperature and emitting shock waves, the latter of which are a source of noise. Although the collapse of a small cavity is a relatively low-energy event, highly localized collapses can erode metals, such as steel, over time. The pitting caused by the collapse of cavities produces great wear on components and can dramatically shorten a propeller or pump’s lifetime.

Cavitation is usually accompanied also by:

- Noise. Typical noise is caused by collapsing cavities. The level of the noise that results from cavitation is a measure of the severity of the cavitation.

- Vibration. Pump vibrations due to cavitation are characteristically low frequency vibrations, usually found in the 0 to 10 Hz range.

- Reduction in pump efficiency. A decrease in efficiency of the pump is a more reliable sign of cavitation occurring.

We hope, this article, Cavitation in Centrifugal Pumps, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.