Laminar Flow

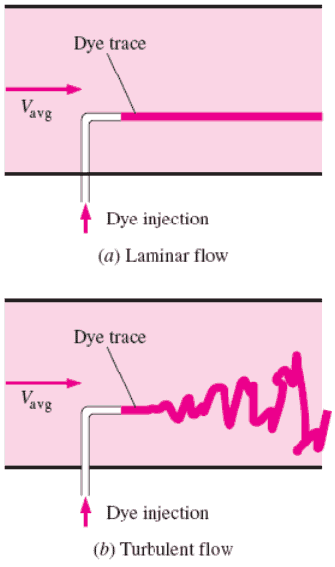

In fluid dynamics, laminar flow is characterized by smooth or in regular paths of particles of the fluid, in contrast to turbulent flow, that is characterized by the irregular movement of particles of the fluid. The fluid flows in parallel layers (with minimal lateral mixing), with no disruption between the layers. Therefore the laminar flow is also referred to as streamline or viscous flow.

The term streamline flow is descriptive of the flow because, in laminar flow, layers of water flowing over one another at different speeds with virtually no mixing between layers, fluid particles move in definite and observable paths or streamlines.

When a fluid is flowing through a closed channel such as a pipe or between two flat plates, either of two types of flow (laminar flow or turbulent flow) may occur depending on the velocity, viscosity of the fluid and the size of the pipe. Laminar flow tends to occur at lower velocities and high viscosity. On the other hand turbulent flow tends to occur at higher velocities and low viscosity.

Since laminar flow is common only in cases in which the flow channel is relatively small, the fluid is moving slowly, and its viscosity is relatively high, laminar flow is not common in industrial processes. Most industrial flows, especially those in nuclear engineering are turbulent. Nevertheless laminar flow occurs at any Reynolds number near solid boundaries in a thin layer just adjacent to the surface, this layer is usually referred to as the laminar sublayer and it is very important in heat transfer.

Despite the small thickness of the laminar sublayer (usually much less than 1 percent of the pipe diameter), since it strongly influences the flow in the rest of the pipe. Any irregularity or roughness on the surface disturbs this layer and significantly affects the flow. Therefore, unlike laminar flow, the friction factor in turbulent flow is a strong function of surface roughness.

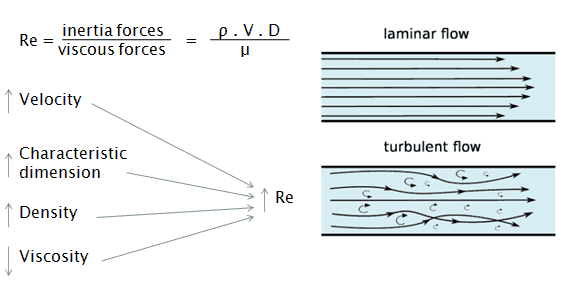

Reynolds Number

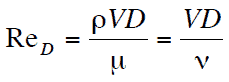

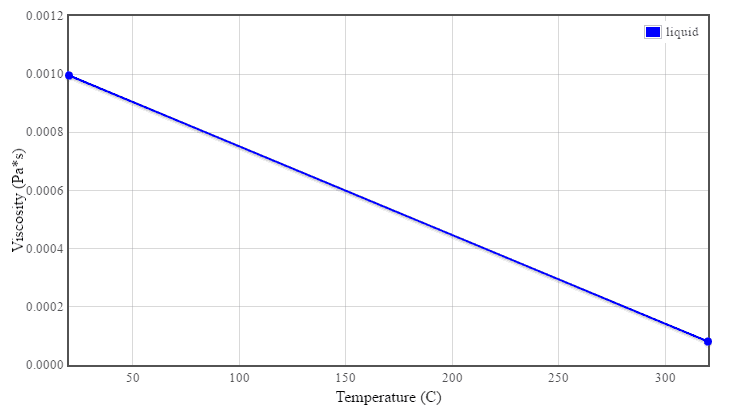

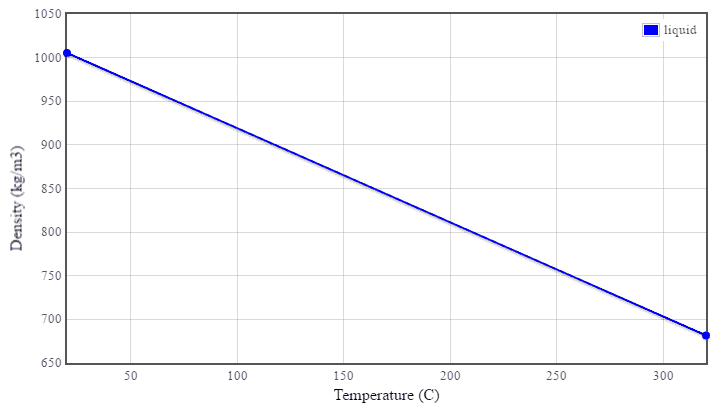

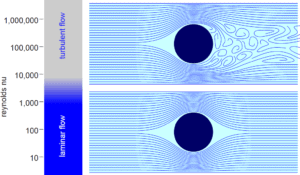

The Reynolds number is the ratio of inertial forces to viscous forces and is a convenient parameter for predicting if a flow condition will be laminar or turbulent. It can be interpreted that when the viscous forces are dominant (slow flow, low Re) they are sufficient enough to keep all the fluid particles in line, then the flow is laminar. Even very low Re indicates viscous creeping motion, where inertia effects are negligible. When the inertial forces dominate over the viscous forces (when the fluid is flowing faster and Re is larger) then the flow is turbulent.

It is a dimensionless number comprised of the physical characteristics of the flow. An increasing Reynolds number indicates an increasing turbulence of flow.

where:

V is the flow velocity,

D is a characteristic linear dimension, (travelled length of the fluid; hydraulic diameter etc.)

ρ fluid density (kg/m3),

μ dynamic viscosity (Pa.s),

ν kinematic viscosity (m2/s); ν = μ / ρ.

Laminar vs. Turbulent Flow

Laminar Flow:

- Re < 2000

- ‘low’ velocity

- Fluid particles move in straight lines

- Layers of water flow over one another at different speeds with virtually no mixing between layers.

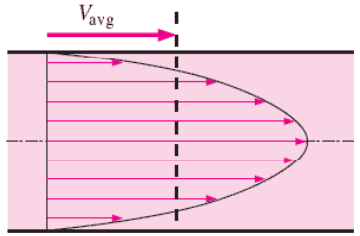

- The flow velocity profile for laminar flow in circular pipes is parabolic in shape, with a maximum flow in the center of the pipe and a minimum flow at the pipe walls.

- The average flow velocity is approximately one half of the maximum velocity.

- Simple mathematical analysis is possible.

- Rare in practice in water systems.

Turbulent Flow:

- Re > 4000

- ‘high’ velocity

- The flow is characterized by the irregular movement of particles of the fluid.

- Average motion is in the direction of the flow

- The flow velocity profile for turbulent flow is fairly flat across the center section of a pipe and drops rapidly extremely close to the walls.

- The average flow velocity is approximately equal to the velocity at the center of the pipe.

- Mathematical analysis is very difficult.

- Most common type of flow.

Reynolds Number Regimes

Laminar flow. For practical purposes, if the Reynolds number is less than 2000, the flow is laminar. The accepted transition Reynolds number for flow in a circular pipe is Red,crit = 2300.

Laminar flow. For practical purposes, if the Reynolds number is less than 2000, the flow is laminar. The accepted transition Reynolds number for flow in a circular pipe is Red,crit = 2300.

Transitional flow. At Reynolds numbers between about 2000 and 4000 the flow is unstable as a result of the onset of turbulence. These flows are sometimes referred to as transitional flows.

Turbulent flow. If the Reynolds number is greater than 3500, the flow is turbulent. Most fluid systems in nuclear facilities operate with turbulent flow.

Laminar Flow – Heat Transfer Coefficient

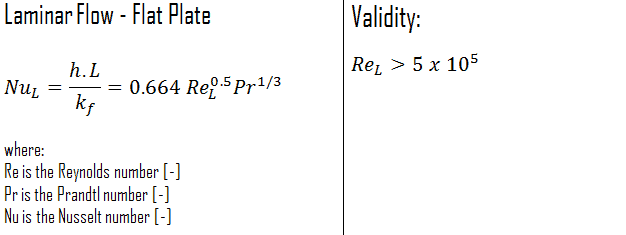

External Laminar Flow

The average Nusselt number over the entire plate is determined by:

This relation gives the average heat transfer coefficient for the entire plate when the flow is laminar over the entire plate.

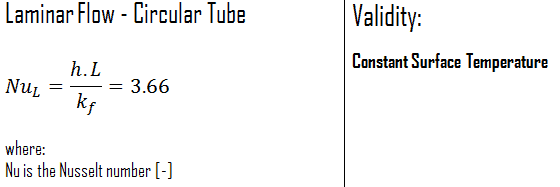

Internal Laminar Flow

Constant Surface Temperature

In laminar flow in a tube with constant surface temperature, both the friction factor and the heat transfer coefficient remain constant in the fully developed region.

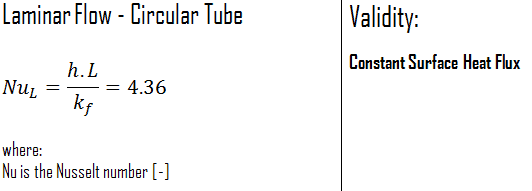

Constant Surface Heat Flux

Therefore, for fully developed laminar flow in a circular tube subjected to constant surface heat flux, the Nusselt number is a constant. There is no dependence on the Reynolds or the Prandtl numbers.

We hope, this article, Laminar Flow – Viscous Flow, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.