Compounding of Steam Turbines

Compounding of steam turbines is the method in which energy from the steam is extracted in a number of stages rather than a single stage in a turbine. In all turbines the rotating blade velocity is proportional to the steam velocity passing over the blade. If the steam is expanded only in a single stage from the boiler pressure to the exhaust pressure, its velocity must be extremely high.

A compounded steam turbine has multiple stages i.e. it has more than one set of nozzles and rotors, in series, keyed to the shaft or fixed to the casing, so that either the steam pressure or the jet velocity is absorbed by the turbine in number of stages. For example, large HP Turbine used in nuclear power plants can be double-flow reaction turbine with about 10 stages with shrouded blades. Large LP turbines used in nuclear power plants are usually double-flow reaction turbines with about 5-8 stages (with shrouded blades and with free-standing blades of last 3 stages).

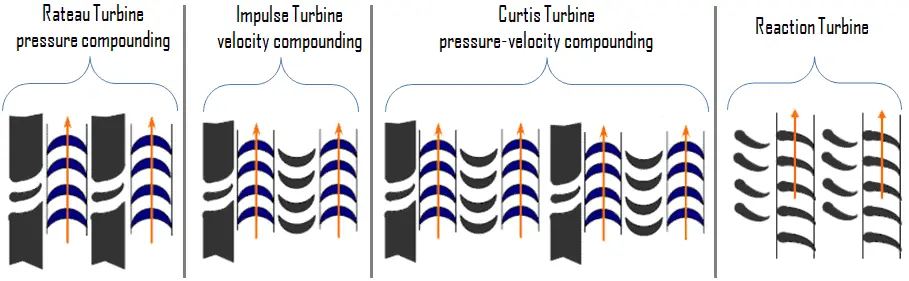

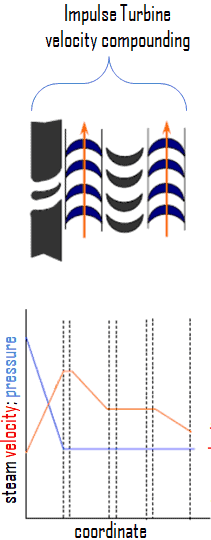

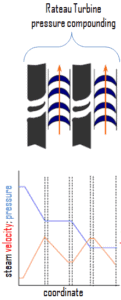

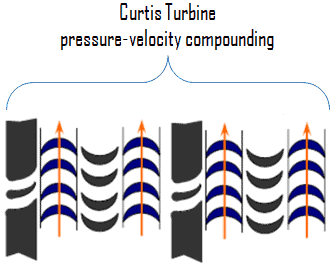

In an impulse steam turbine compounding can be achieved in the following three ways:

- pressure compounding

- velocity compounding

- pressure-velocity compounding

We hope, this article, Compounding of Steam Turbines, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.