Condensation Modes – Types of Condensation. From a practical engineering point of view condensation can be categorized according to several criteria. Thermal Engineering

Condensation Modes – Types of Condensation

From a practical engineering point of view condensation can be categorized according to several criteria.

In general, three distinct forms of condensation are observed:

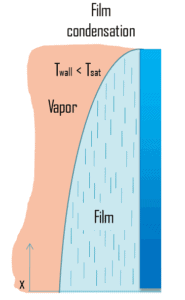

- Film condensation. In film condensation, the condensate wets the surface and forms a liquid film on the surface that slides down under the influence of gravity. Film condensation results in low heat transfer rates as the film of condensate impedes the heat transfer. The thickness of the film formed depends on many parameters including orientation of the surface, viscosity, rate of condensation etc. The film increases a thermal resistance to heat flow between the surface and the vapour. The rate of heat transfer is reduced because of this resistance.

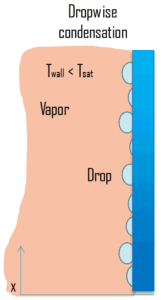

- Dropwise condensation. In dropwise condensation, the condensed vapor forms droplets on the surface instead of a continuous film. Dropwise condensation can occur when the surface is nonwetting or these droplets are taken away from the surface by external flow or by gravity. The vapour is in direct contact with the surface over most of the area and heat transfer rates are much higher (more than 3 – 10 times higher) as there is very little resistance for heat flow between the vapour and the surface. The droplets develop at nucleation sites (points of surface imperfections such as pit, scratch and cavities), and grow in size as more vapour condenses on its exposed surface. For steam condensers, it is common practice to use surface coatings (silicons, teflons or waxes) that inhibit wetting, and hence stimulate dropwise condensation. But coatings gradually lose their effectiveness due to removal, oxidation etc. In practice no surface is found to continue as nonwetting over any length of time. Since in most engineering applications it is often difficult to maintain this condition, using the value of heat transfer coefficients assuming dropwise condensation for design purposes is not advisable.

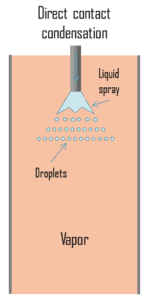

- Direct contact condensation. Direct contact condensation, DCC, occurs when vapor is brought into contact with a cold liquid. As in jet condensers, the cooling water is sprayed on the exhaust steam and there is direct contact between the exhaust steam and cooling water. The process of condensation is very fast and efficient, but here cooling water and condensed steam are mixed up. The advantages of direct contact condensation over the conventional processes using metallic transfer surfaces are due to the relative simplicity of design, less corrosion and scaling problems, lower maintenance costs, higher specific transfer areas, and higher transfer rates. Despite these advantages jet condensers are not usual in thermal power plants especially due to the loss of condensate.

We hope, this article, Condensation Mode – Types of Condensation, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.