Supercritical Water Reactor – SCWR

Author (Public domain): U.S. Department of Energy

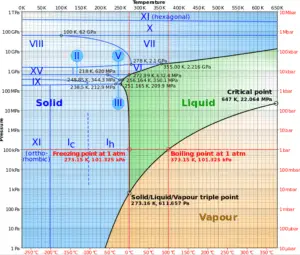

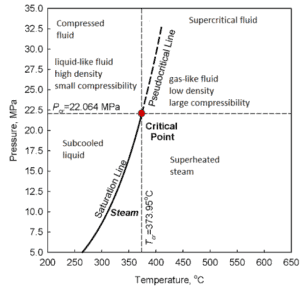

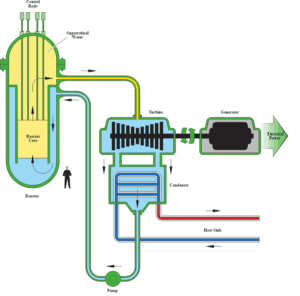

The supercritical water reactor (SCWR) is a concept of Generation IV reactor, that is operated at supercritical pressure (i.e. greater than 22.1 MPa). The term supercritical in this context refers to the thermodynamic critical point of water (TCR = 374 °C; pCR = 22.1 MPa), and must not be confused with the criticality of the reactor core, that describes changes in the neutron population in the reactor core.

The supercritical water reactor may be operated as a thermal reactor or as a fast-neutron reactor, depending on the core design. The concept of the supercritical water reactor may be based on classical pressure vessel as in commercial PWRs or on pressure tubes as in CANDU reactors. The pressure-vessel design of supercritical water reactors is developed largely in the EU, US, Japan, Korea, and China, while the pressure-channel design is developed largely in Canada and in Russia. The pressure-vessel design allows using a traditional high-pressure circuit layout. The pressure-channel design allows the key features of passive accident and decay heat removal by radiation and convection from the distributed channels even with no active cooling and fuel melting and use of multi-pass reactor flows making reheating and superheating possible.

For both pressure vessel and pressure-tube designs, a once through steam cycle has been envisaged, omitting any coolant recirculation inside the reactor. It is similar as in boiling water reactors, steam will be supplied directly to the steam turbine and the feed water from the steam cycle will be supplied back to the core.

As well as the supercritical water reactor may use light water or heavy water as neutron moderator. As can be seen, there are many SCWR designs, but all SCWRs have a key feature, that is the use of water beyond the thermodynamic critical point as primary coolant. Since this feature allows to increase the peak temperature, the supercritical water reactors are considered a promising advancement for nuclear power plants because of its high thermal efficiency (~45 % vs. ~33 % for current LWRs).

Advantages and Challenges of SCWRs

As can be inferred from its name, the SCWR’s key feature is the use of water beyond the thermodynamic critical point (TCR = 374 °C; pCR = 22.1 MPa) as primary coolant. SCWR designs have unique features that offer many advantages compared to current light water reactors (LWRs).

As can be inferred from its name, the SCWR’s key feature is the use of water beyond the thermodynamic critical point (TCR = 374 °C; pCR = 22.1 MPa) as primary coolant. SCWR designs have unique features that offer many advantages compared to current light water reactors (LWRs).

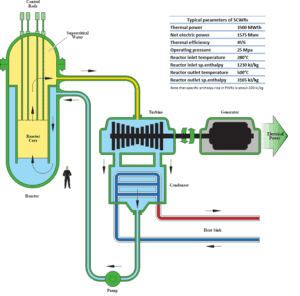

- High thermal efficiency. Since SCWRs supply supercritical steam at pressures and temperatures, that are much higher than in conventional LWRs, they will reach higher thermodynamic efficiency of the power plant (~45 % vs. ~33 % for current LWRs).

- Lower coolant mass flow rate. The reactor coolant flow rate of SCWR is much smaller than that of BWR and PWR because the enthalpy rise in the core is much larger, which results in low capacity components of the primary system. Thus, the coolant pumps, pipes and other supporting equipment become smaller. Moreover, the only pumps driving the coolant under normal operating conditions are the feed water pumps and the condensate extraction pumps.

- The higher steam enthalpy allows to decrease the size of the turbine system and thus to lower the capital costs of the conventional island.

- Smaller coolant inventory. The coolant inventory is smaller which reduces the size of the containment with pressure suppression pools.

- Since supercritical water does not undergo a phase change and it exists in a single thermodynamic phase, the boiling crisis (i.e. departure from nucleate boiling – DNB or dry out) cannot occur.

- With a direct cycle of supercritical coolant, components like steam dryers, separators and steam generators are omitted entirely, reducing the number of major components and eliminating their associated costs.

- Many of the components (e.g. turbine) are readily developed and available from supercritical fossil fired power plants.

The combination of advanced water-cooled reactor technology and advanced supercritical fossil technology is expected to result in a reactor concept that can be used to generate base-load electricity very economically and efficiently. This feature also makes the SCWR a very attractive concept for utilities, especially those that have experience with both water-cooled reactors and supercritical fossil plants.

On the other hand numerous challenges must be solved before the first power plants of this type can be built:

- The cladding materials have to withstand higher temperatures (600-650°C in normal operating conditions) than in today’s LWRs.

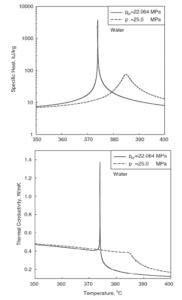

- The heat transfer phenomena from cladding surface into supercritical fluid must be understood thoroughly. Especially in case of within transients with depressurization from supercritical to subcritical conditions.

- Due to the smaller coolant inventory, the dry out of the core progresses faster in case of a loss of coolant accident (LOCA).

Characteristics of SCWRs

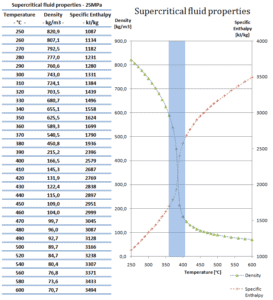

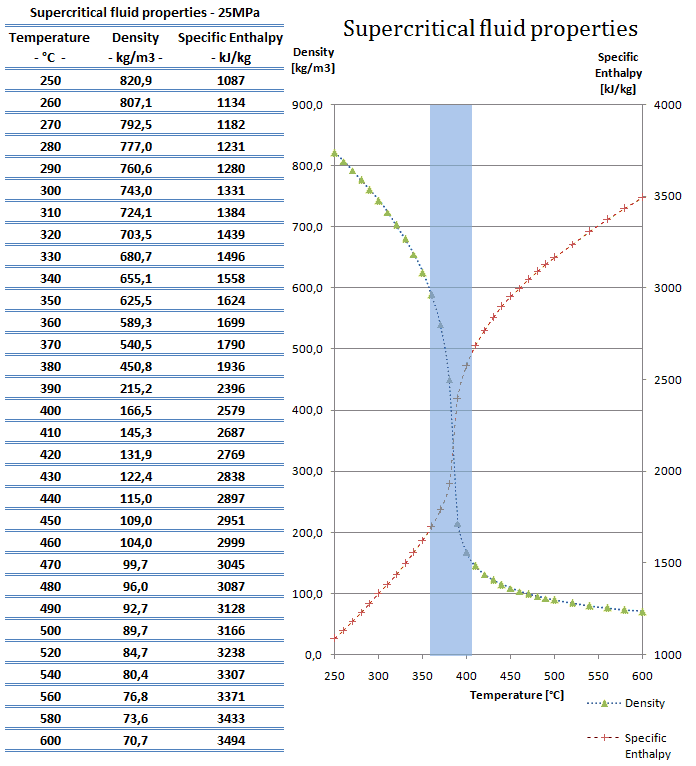

- the density of supercritical water at the inlet and at the outlet is about 777 kg/m3 (for 25MPa and 280°C) and 90 kg/m3 (for 25MPa and 500°C),

- the specific enthalpy of supercritical water at the inlet and at the outlet is about 1230 kJ/kg (for 25MPa and 280°C) and 3165 kJ/kg (for 25MPa and 500°C)

From a neutronics point of view, the density of water is the most important factor. There is a significant change of neutron spectrum, which changes with the axial coordinate of the core. It is caused by the greater moderation in places with greater density. For this reason, a coupled neutronics – thermal hydraulics calculation is inevitable to obtain neutron flux distribution within the core. In each nuclear reactor, there is a direct proportionality between the neutron flux and the reactor thermal power.

Since the coolant (moderator) undergo significant change in density, the SCWR can also be designed as a fast neutron reactor. This property depends on certain reactor design.

We hope, this article, Supercritical Water Reactor – SCWR, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.