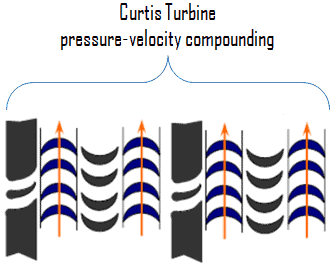

Pressure-Velocity Compounding – Curtis Turbine

Impulse stages may be either pressure-compounded, velocity-compounded, or pressure-velocity compounded. The pressure-velocity compounding is a combination of the above two types of compounding. In fact, a series of velocity-compounded impulse stages is called a pressure-velocity compounded turbine. Each stage consists of rings of fixed and moving blades. Each set of rings of moving blades is separated by a single ring of fixed nozzles. In each stage there is one ring of fixed nozzles and 3-4 rings of moving blades (with fixed blades between them). Each stage acts as a velocity compounded impulse turbine.

The steam coming from the steam generator is passed to the first ring of fixed nozzles, where it gets partially expanded. The pressure partially decreases and the velocity rises correspondingly. It then passes over the 3-4 rings of moving blades (with fixed blades between them) where nearly all of its velocity is absorbed. From the last ring of the stage it exhausts into the next nozzle ring and is again partially expanded.

This has the advantage of allowing a bigger pressure drop in each stage and, consequently, less stages are necessary, resulting in a shorter turbine for a given pressure drop. It may be seen that the pressure is constant during each stage; the turbine is, therefore, an impulse turbine. The method of pressure-velocity compounding is used in the Curtis turbine.

We hope, this article, Pressure-Velocity Compounding – Curtis Turbine, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.