Fouling – Fouling Factor

Online monitoring of commercial heat exchangers is done by tracking the overall heat transfer coefficient, because the overall heat transfer coefficient tends to decline over time due to fouling. Fouling is the accumulation of unwanted material on solid surfaces to the detriment of function. The fouling materials can consist of either living organisms or a non-living substance (minerals or organic compounds). The layer of deposits represents additional resistance to heat transfer and causes the rate of heat transfer in a heat exchanger to decrease. As a result, fouling in heat exchangers reduces thermal efficiency, decreases heat flux, increases temperature on the hot side, decreases temperature on the cold side, induces under-deposit corrosion, increases use of cooling water. The net effect of these accumulations on heat transfer is represented by a fouling factor, Rf , which is a measure of the overall thermal resistance introduced by fouling.

Overall Heat Transfer Coefficient

A heat exchanger typically involves two flowing fluids separated by a solid wall. Many of the heat transfer processes encountered in industry involve composite systems and even involve a combination of both conduction and convection. Heat is first transferred from the hot fluid to the wall by convection, through the wall by conduction, and from the wall to the cold fluid again by convection.

A heat exchanger typically involves two flowing fluids separated by a solid wall. Many of the heat transfer processes encountered in industry involve composite systems and even involve a combination of both conduction and convection. Heat is first transferred from the hot fluid to the wall by convection, through the wall by conduction, and from the wall to the cold fluid again by convection.

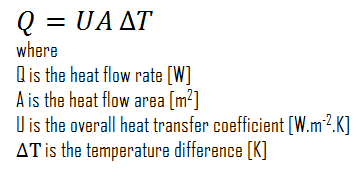

With these composite systems, it is often convenient to work with an overall heat transfer coefficient, known as a U-factor. The U-factor is defined by an expression analogous to Newton’s law of cooling:

The overall heat transfer coefficient, U, is related to the total thermal resistance and depends on the geometry of the problem. For example, heat transfer in a steam generator involves convection from the bulk of the reactor coolant to the steam generator inner tube surface, conduction through the tube wall, and convection (boiling) from the outer tube surface to the secondary side fluid.

In cases of combined heat transfer for a heat exchanger, there are two values for h. There is the convective heat transfer coefficient (h) for the fluid film inside the tubes and a convective heat transfer coefficient for the fluid film outside the tubes. The thermal conductivity (k) and thickness (Δx) of the tube wall must also be accounted for.

We hope, this article, Fouling – Fouling Factor, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.