Expanded Polystyrene – EPS

Generally, polystyrene is a synthetic aromatic polymer made from the monomer styrene, which is derived from benzene and ethylene, both petroleum products. Polystyrene can be solid or foamed. Polystyrene is a colorless, transparent thermoplastic, which is commonly used to make foam board or beadboard insulation and a type of loose-fill insulation consisting of small beads of polystyrene. Polystyrene foams are 95-98% air. Polystyrene foams are good thermal insulators and are therefore often used as building insulation materials, such as in insulating concrete forms and structural insulated panel building systems. Expanded (EPS) and extruded polystyrene (XPS) are both made from polystyrene, but EPS is composed of small plastic beads that are fused together and XPS begins as a molten material that is pressed out of a form into sheets. XPS is most commonly used as foam board insulation.

Expanded polystyrene (EPS) is a rigid and tough, closed-cell foam. Building and construction applications account for around two-thirds of demand for expanded polystyrene. It is used for the insulation of (cavity) walls, roofs and concrete floors. Due to its technical properties such as low weight, rigidity, and formability, expanded polystyrene can be used in a wide range of applications, for example trays, plates and fish boxes.

Although both expanded and extruded polystyrene have a closed-cell structure, they are permeable by water molecules and can not be considered a vapor barrier. In expanded polystyrene there are interstitial gaps between the expanded closed-cell pellets that form an open network of channels between the bonded pellets. If the water freezes into ice, it expands and can cause polystyrene pellets to break off from the foam.

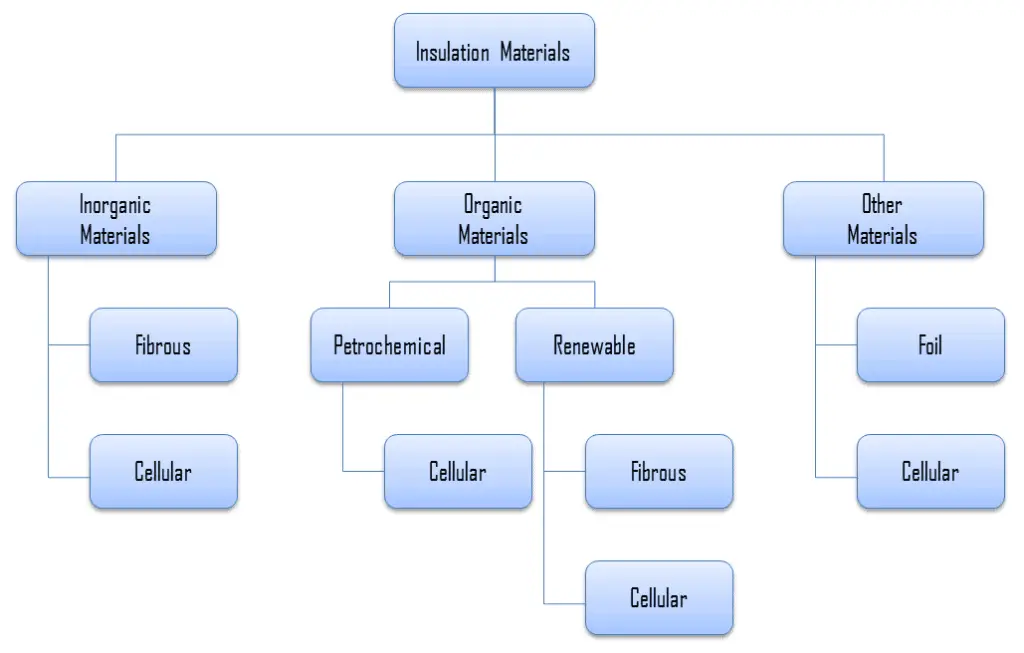

Thermal Conductivity of Expanded Polystyrene

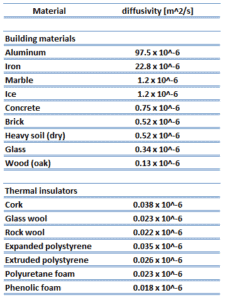

Thermal conductivity is defined as the amount of heat (in watts) transferred through a square area of material of given thickness (in metres) due to a difference in temperature. The lower the thermal conductivity of the material the greater the material’s ability to resist heat transfer, and hence the greater the insulation’s effectiveness. Typical thermal conductivity values for expanded polystyrene are between 0.030 and 0.040W/m∙K.

Thermal conductivity is defined as the amount of heat (in watts) transferred through a square area of material of given thickness (in metres) due to a difference in temperature. The lower the thermal conductivity of the material the greater the material’s ability to resist heat transfer, and hence the greater the insulation’s effectiveness. Typical thermal conductivity values for expanded polystyrene are between 0.030 and 0.040W/m∙K.

In general, thermal insulation is primarily based on the very low thermal conductivity of gases. Gases possess poor thermal conduction properties compared to liquids and solids, and thus makes a good insulation material if they can be trapped (e.g. in a foam-like structure). Air and other gases are generally good insulators. But the main benefit is in the absence of convection. Therefore, many insulating materials (e.g. expanded polystyrene) function simply by having a large number of gas-filled pockets which prevent large-scale convection.

Alternation of gas pocket and solid material causes that the heat must be transferred through many interfaces causing rapid decrease in heat transfer coefficient.

Example – Expanded Polystyrene Insulation

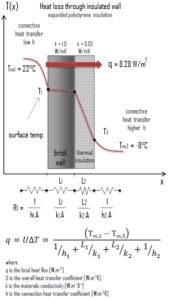

A major source of heat loss from a house is through walls. Calculate the rate of heat flux through a wall 3 m x 10 m in area (A = 30 m2). The wall is 15 cm thick (L1) and it is made of bricks with the thermal conductivity of k1 = 1.0 W/m.K (poor thermal insulator). Assume that, the indoor and the outdoor temperatures are 22°C and -8°C, and the convection heat transfer coefficients on the inner and the outer sides are h1 = 10 W/m2K and h2 = 30 W/m2K, respectively. Note that, these convection coefficients strongly depend especially on ambient and interior conditions (wind, humidity, etc.).

A major source of heat loss from a house is through walls. Calculate the rate of heat flux through a wall 3 m x 10 m in area (A = 30 m2). The wall is 15 cm thick (L1) and it is made of bricks with the thermal conductivity of k1 = 1.0 W/m.K (poor thermal insulator). Assume that, the indoor and the outdoor temperatures are 22°C and -8°C, and the convection heat transfer coefficients on the inner and the outer sides are h1 = 10 W/m2K and h2 = 30 W/m2K, respectively. Note that, these convection coefficients strongly depend especially on ambient and interior conditions (wind, humidity, etc.).

- Calculate the heat flux (heat loss) through this non-insulated wall.

- Now assume thermal insulation on the outer side of this wall. Use expanded polystyrene insulation 10 cm thick (L2) with the thermal conductivity of k2 = 0.03 W/m.K and calculate the heat flux (heat loss) through this composite wall.

Solution:

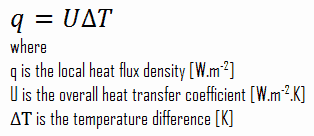

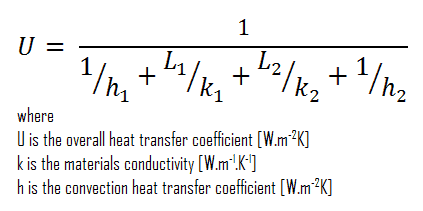

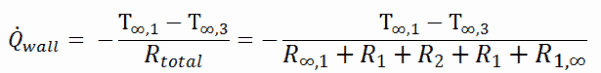

As was written, many of the heat transfer processes involve composite systems and even involve a combination of both conduction and convection. With these composite systems, it is often convenient to work with an overall heat transfer coefficient, known as a U-factor. The U-factor is defined by an expression analogous to Newton’s law of cooling:

The overall heat transfer coefficient is related to the total thermal resistance and depends on the geometry of the problem.

- bare wall

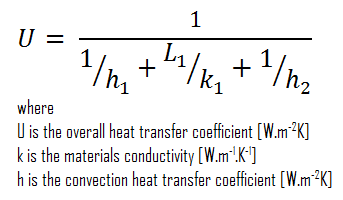

Assuming one-dimensional heat transfer through the plane wall and disregarding radiation, the overall heat transfer coefficient can be calculated as:

The overall heat transfer coefficient is then:

U = 1 / (1/10 + 0.15/1 + 1/30) = 3.53 W/m2K

The heat flux can be then calculated simply as:

q = 3.53 [W/m2K] x 30 [K] = 105.9 W/m2

The total heat loss through this wall will be:

qloss = q . A = 105.9 [W/m2] x 30 [m2] = 3177W

- composite wall with thermal insulation

Assuming one-dimensional heat transfer through the plane composite wall, no thermal contact resistance and disregarding radiation, the overall heat transfer coefficient can be calculated as:

The overall heat transfer coefficient is then:

The overall heat transfer coefficient is then:

U = 1 / (1/10 + 0.15/1 + 0.1/0.03 + 1/30) = 0.276 W/m2K

The heat flux can be then calculated simply as:

q = 0.276 [W/m2K] x 30 [K] = 8.28 W/m2

The total heat loss through this wall will be:

qloss = q . A = 8.28 [W/m2] x 30 [m2] = 248 W

As can be seen, an addition of thermal insulator causes significant decrease in heat losses. It must be added, an addition of next layer of thermal insulator does not cause such high savings. This can be better seen from the thermal resistance method, which can be used to calculate the heat transfer through composite walls. The rate of steady heat transfer between two surfaces is equal to the temperature difference divided by the total thermal resistance between those two surfaces.

We hope, this article, Expanded Polystyrene – EPS, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.