Classification of Flow Regimes

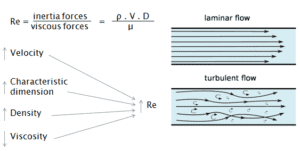

Another usually more common classification of flow regimes is according to the shape and type of streamlines. All fluid flow is classified into one of two broad categories. The fluid flow can be either laminar or turbulent and therefore these two categories are:

Another usually more common classification of flow regimes is according to the shape and type of streamlines. All fluid flow is classified into one of two broad categories. The fluid flow can be either laminar or turbulent and therefore these two categories are:

Laminar flow is characterized by smooth or in regular paths of particles of the fluid. Therefore the laminar flow is also referred to as streamline or viscous flow. In contrast to laminar flow, turbulent flow is characterized by the irregular movement of particles of the fluid. The turbulent fluid does not flow in parallel layers, the lateral mixing is very high, and there is a disruption between the layers. Most industrial flows, especially those in nuclear engineering are turbulent.

Laminar Flow

In fluid dynamics, laminar flow is characterized by smooth or in regular paths of particles of the fluid, in contrast to turbulent flow, that is characterized by the irregular movement of particles of the fluid. The fluid flows in parallel layers (with minimal lateral mixing), with no disruption between the layers. Therefore the laminar flow is also referred to as streamline or viscous flow.

The term streamline flow is descriptive of the flow because, in laminar flow, layers of water flowing over one another at different speeds with virtually no mixing between layers, fluid particles move in definite and observable paths or streamlines.

When a fluid is flowing through a closed channel such as a pipe or between two flat plates, either of two types of flow (laminar flow or turbulent flow) may occur depending on the velocity, viscosity of the fluid and the size of the pipe. Laminar flow tends to occur at lower velocities and high viscosity. On the other hand turbulent flow tends to occur at higher velocities and low viscosity.

Since laminar flow is common only in cases in which the flow channel is relatively small, the fluid is moving slowly, and its viscosity is relatively high, laminar flow is not common in industrial processes. Most industrial flows, especially those in nuclear engineering are turbulent. Nevertheless laminar flow occurs at any Reynolds number near solid boundaries in a thin layer just adjacent to the surface, this layer is usually referred to as the laminar sublayer and it is very important in heat transfer.

See also: Reynolds Number

See also: Critical Reynolds Number

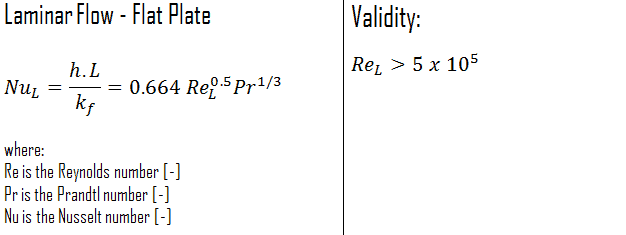

External Laminar Flow – Nusselt Number

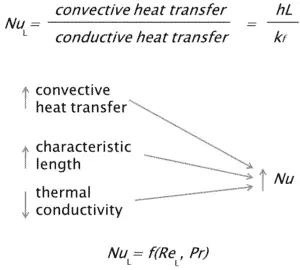

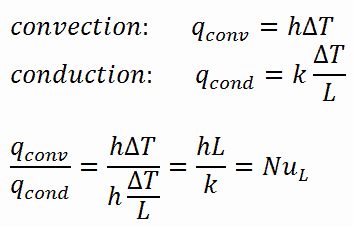

The average Nusselt number over the entire plate is determined by:

This relation gives the average heat transfer coefficient for the entire plate when the flow is laminar over the entire plate.

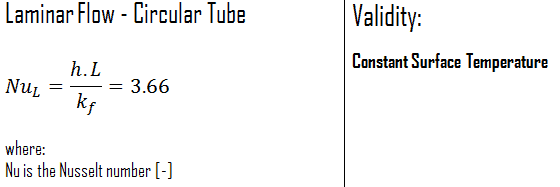

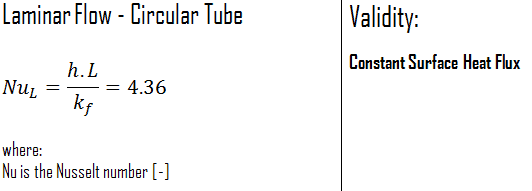

Internal Laminar Flow – Nusselt Number

Constant Surface Temperature

In laminar flow in a tube with constant surface temperature, both the friction factor and the heat transfer coefficient remain constant in the fully developed region.

Constant Surface Heat Flux

Therefore, for fully developed laminar flow in a circular tube subjected to constant surface heat flux, the Nusselt number is a constant. There is no dependence on the Reynolds or the Prandtl numbers.

Turbulent Flow

In fluid dynamics, turbulent flow is characterized by the irregular movement of particles (one can say chaotic) of the fluid. In contrast to laminar flow the fluid does not flow in parallel layers, the lateral mixing is very high, and there is a disruption between the layers. Turbulence is also characterized by recirculation, eddies, and apparent randomness. In turbulent flow the speed of the fluid at a point is continuously undergoing changes in both magnitude and direction.

Detailed knowledge of behaviour of turbulent flow regime is of importance in engineering, because most industrial flows, especially those in nuclear engineering are turbulent. Unfortunately, the highly intermittent and irregular character of turbulence complicates all analyses. In fact, turbulence is often said to be the “last unsolved problem in classical mathemetical physics.”

The main tool available for their analysis is CFD analysis. CFD is a branch of fluid mechanics that uses numerical analysis and algorithms to solve and analyze problems that involve turbulent fluid flows. It is widely accepted that the Navier–Stokes equations (or simplified Reynolds-averaged Navier–Stokes equations) are capable of exhibiting turbulent solutions, and these equations are the basis for essentially all CFD codes.

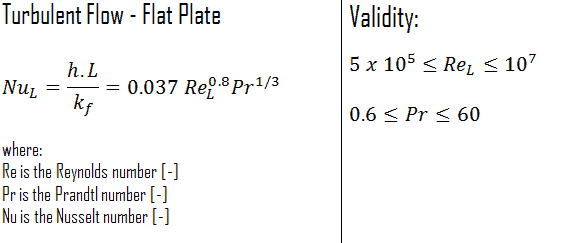

External Turbulent Flow – Nusselt Number

The average Nusselt number over the entire plate is determined by:

This relation gives the average heat transfer coefficient for the entire plate only when the flow is turbulent over the entire plate, or when the laminar flow region of the plate is too small relative to the turbulent flow region.

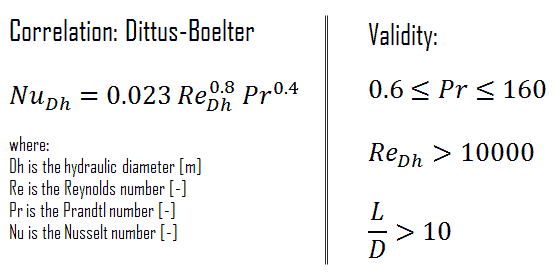

Internal Turbulent Flow – Nusselt Number

See also: Dittus-Boelter Equation

For fully developed (hydrodynamically and thermally) turbulent flow in a smooth circular tube, the local Nusselt number may be obtained from the well-known Dittus-Boelter equation. The DittusBoelter equation is easy to solve but is less accurate when there is a large temperature difference across the fluid and is less accurate for rough tubes (many commercial applications), since it is tailored to smooth tubes.

The Dittus-Boelter correlation may be used for small to moderate temperature differences, Twall – Tavg, with all properties evaluated at an averaged temperature Tavg.

For flows characterized by large property variations, the corrections (e.g. a viscosity correction factor μ/μwall) must be taken into account, for example, as Sieder and Tate recommend.

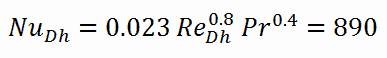

Calculation of the Nusselt number using Dittus-Boelter equation

For fully developed (hydrodynamically and thermally) turbulent flow in a smooth circular tube, the local Nusselt number may be obtained from the well-known DittusBoelter equation.

To calculate the Nusselt number, we have to know:

- the Reynolds number, which is ReDh = 575600

- the Prandtl number, which is Pr = 0.89

The Nusselt number for the forced convection inside the fuel channel is then equal to:

We hope, this article, Laminar vs Turbulent – Nusselt Number, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.