Major Head Loss – Frictional Loss

Major losses, which are associated with frictional energy loss per length of pipe depends on the flow velocity, pipe length, pipe diameter, and a friction factor based on the roughness of the pipe, and whether the flow is laminar or turbulent (i.e. the Reynolds number of the flow).

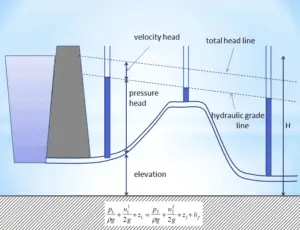

Although the head loss represents a loss of energy, it does not represent a loss of total energy of the fluid. The total energy of the fluid conserves as a consequence of the law of conservation of energy. In reality, the head loss due to friction results in an equivalent increase in the internal energy (increase in temperature) of the fluid.

By observation, the major head loss is roughly proportional to the square of the flow rate in most engineering flows (fully developed, turbulent pipe flow).

The most common equation used to calculate major head losses in a tube or duct is the Darcy–Weisbach equation .

Darcy-Weisbach Equation

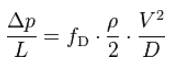

In fluid dynamics, the Darcy–Weisbach equation is a phenomenological equation, which relates the major head loss, or pressure loss, due to fluid friction along a given length of pipe to the average velocity. This equation is valid for fully developed, steady, incompressible single-phase flow.

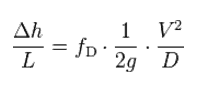

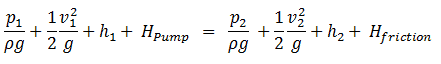

The Darcy–Weisbach equation can be written in two forms (pressure loss form or head loss form). In the head loss form can be written as:

where:

- Δh = the head loss due to friction (m)

- fD = the Darcy friction factor (unitless)

- L = the pipe length (m)

- D = the hydraulic diameter of the pipe D (m)

- g = the gravitational constant (m/s2)

- V = the mean flow velocity V (m/s)

Summary:

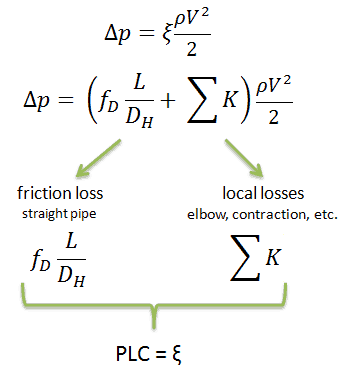

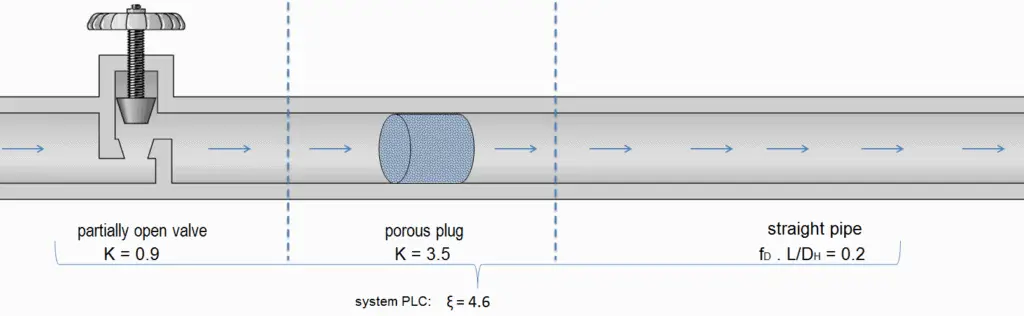

- Head loss of hydraulic system is divided into two main categories:

- Major Head Loss – due to friction in straight pipes

- Minor Head Loss – due to components as valves, bends…

- Darcy’s equation can be used to calculate major losses.

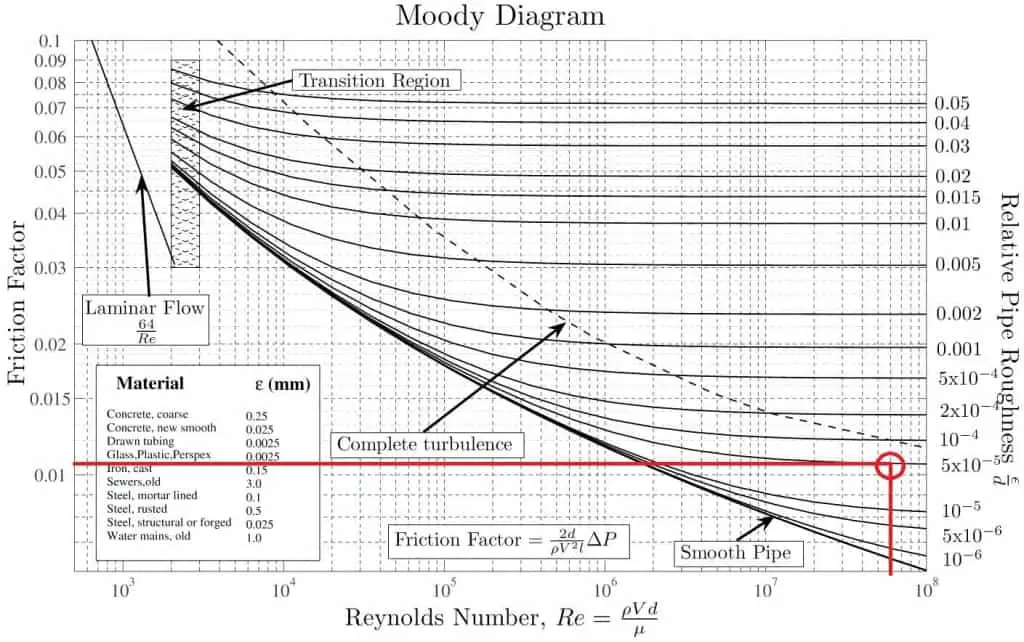

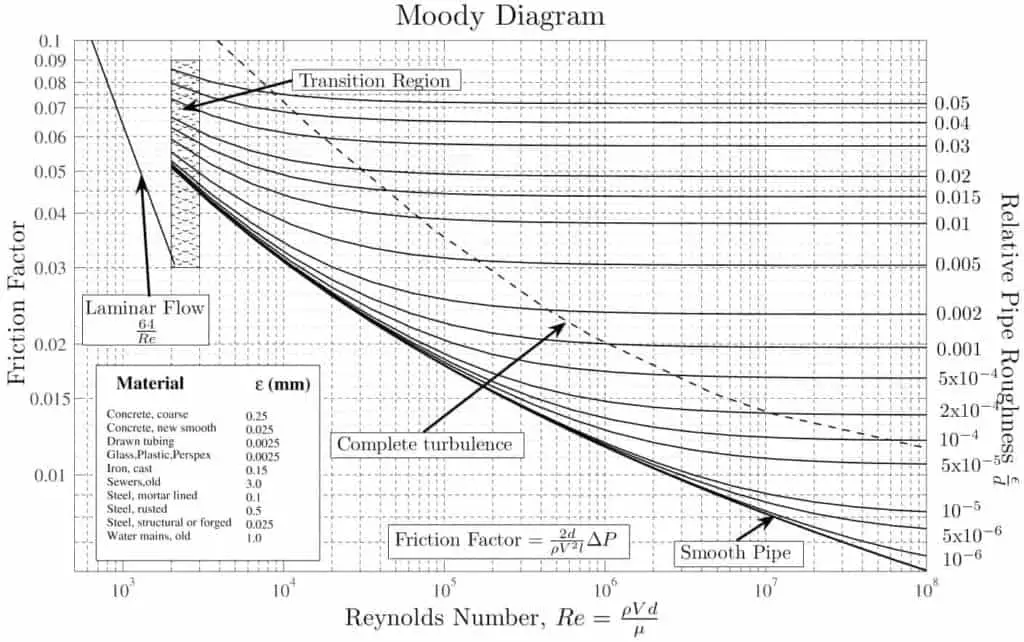

- The friction factor for fluid flow can be determined using a Moody chart.

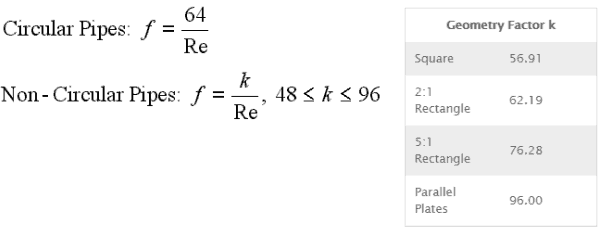

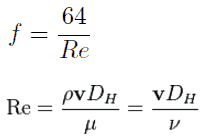

- The friction factor for laminar flow is independent of roughness of the pipe’s inner surface. f = 64/Re

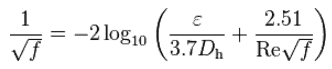

- The friction factor for turbulent flow depends strongly on the relative roughness. It is determined by the Colebrook equation. It must be noted, at very large Reynolds numbers, the friction factor is independent of the Reynolds number.

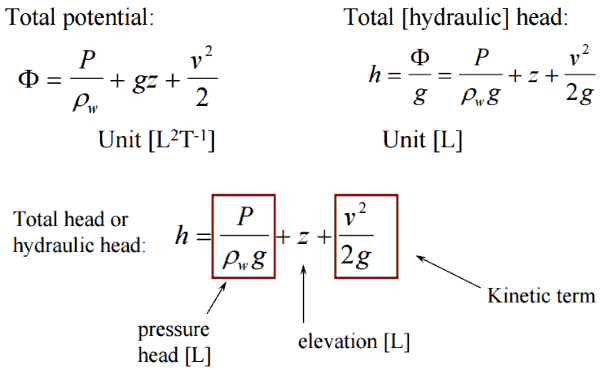

Why the head loss is very important?

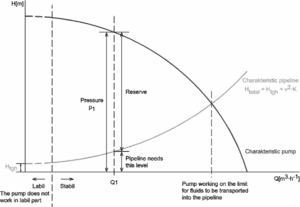

As can be seen from the picture, the head loss is forms key characteristic of any hydraulic system. In systems, in which some certain flowrate must be maintained (e.g. to provide sufficient cooling or heat transfer from a reactor core), the equilibrium of the head loss and the head added by a pump determines the flowrate through the system.

- Consider that the length of the pipe or channel is doubled, the resulting frictional head loss will double.

- At constant flow rate and pipe length, the head loss is inversely proportional to the 4th power of diameter (for laminar flow), and thus reducing the pipe diameter by half increases the head loss by a factor of 16. This is a very significant increase in head loss, and shows why larger diameter pipes lead to much smaller pumping power requirements.

- Since the head loss is roughly proportional to the square of the flow rate, then if the flow rate is doubled, the head loss increases by a factor of four.

- The head loss is reduced by half (for laminar flow) when the viscosity of the fluid is reduced by half.

https://commons.wikimedia.org/w/index.php?curid=4681366

With the exception of the Darcy friction factor, each of these terms (the flow velocity, the hydraulic diameter, the length of a pipe) can be easily measured. The Darcy friction factor takes the fluid properties of density and viscosity into account, along with the pipe roughness. This factor may be evaluated by the use of various empirical relations, or it may be read from published charts (e.g. Moody chart).

Darcy Friction Factor

There are two common friction factors in use, the Darcy and the Fanning friction factors.

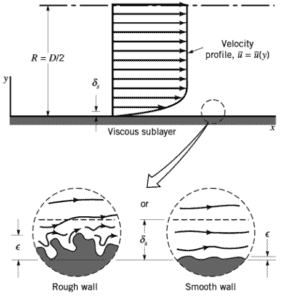

The friction factor has been determined to depend on the Reynolds number for the flow and the degree of roughness of the pipe’s inner surface (especially for turbulent flow). The friction factor of laminar flow is independent of roughness of the pipe’s inner surface.

The pipe cross-section is also important, as deviations from circular cross-section will cause secondary flows that increase the head loss. Non-circular pipes and ducts are generally treated by using the hydraulic diameter.

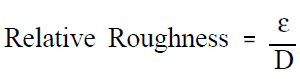

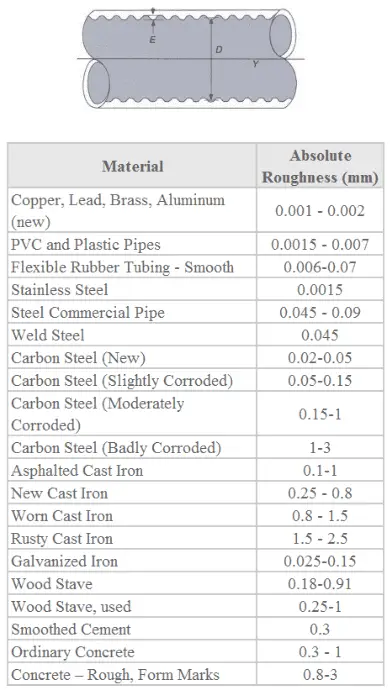

Relative Roughness

The quantity used to measure the roughness of the pipe’s inner surface is called the relative roughness, and it is equal to the average height of surface irregularities (ε) divided by the pipe diameter (D).

,where both the average height surface irregularities and the pipe diameter are in millimeters.

If we know the relative roughness of the pipe’s inner surface, then we can obtain the value of the friction factor from the Moody Chart.

The Moody chart (also known as the Moody diagram) is a graph in non-dimensional form that relates the Darcy friction factor, Reynolds number, and the relative roughness for fully developed flow in a circular pipe.

Darcy Friction Factor for various flow regime

The most common classification of flow regimes is according to the Reynolds number. The Reynolds number is a dimensionless number comprised of the physical characteristics of the flow and it determines whether the flow is laminar or turbulent. An increasing Reynolds number indicates an increasing turbulence of flow. As can be seen from the Moody chart, also Darcy friction factor is highly dependent on the flow regime (i.e. on the Reynolds number).

Examples

We hope, this article, Major Head Loss – Friction Loss, helps you. If so, give us a like in the sidebar. Main purpose of this website is to help the public to learn some interesting and important information about thermal engineering.